When it comes to product development, market successes and remarkable prototypes are often distinguished by speed, accuracy, and adaptability. Sheet metal prototyping in China excels in this situation, not as a fallback choice, but as a vital component of early product success.

Imagine having a working prototype in your hands the week after you sketched a design today. That is the power of sheet metal. Sheet metal enables producers to rapidly test, iterate, and refine creations before investing large sums of money in full-scale production, from consumer electronics to aerospace components.

Not Just Metal, It’s a Mindset

Sheet metal is more than just a substance. It's a dedication to adaptability, reactivity, and practical validation. Sheet metal can be cut, bent, and assembled with little initial expenditure, when compared to 3D printing or injection molding, which frequently call for substantial prototype tools. Greater testing and feedback will result in better products.

Sheet metal is a go-to option in sectors like industrial manufacturing and the automotive industry. Do you need to test a component under stress? Do you want to test how your product responds to stress, heat, or vibration? Sheet metal prototypes can withstand the heat, both literally and figuratively, without breaking the bank.

Speed is Everything

Speed is more important than perfection in the early phases of product development. Speed to feedback. Speed to iteration. Speed to clarity. Momentum is killed by conventional techniques that require lengthy delays for tools or materials.

With China sheet metal prototyping, your concept goes from computer-aided design to practical implementation in a matter of days rather than weeks. Engineers can test tolerances, designers can improve aesthetics, and product managers can confirm market fit without completely stopping development.

Precision Without the Pressure

Sheet metal offers a special benefit to both large-scale enterprises and startups: precision without pressure. Do you require hundreds of prototypes? Alright. Do you require a single, exquisitely detailed housing unit? Also, fine.

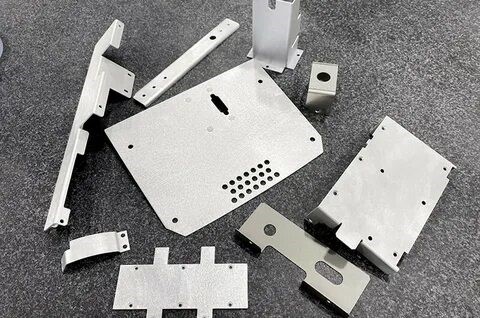

Advanced CNC laser cutting, bending, and welding technologies are used in modern prototyping. These are sophisticated procedures that yield industrial-grade outcomes at a fraction of the cost and lead time of conventional approaches; they are not simple do-it-yourself tasks.

The Bridge to Scalable Production

Success with an early product depends on more than just having a nice prototype. Sheet metal provides the ideal transition to mass production. Your prototype is a tried-and-tested, working component of your production schedule, not a disposable item.

Moreover, prototyping tooling can easily evolve into longer-lasting, more robust tooling solutions as your concept develops. Imagine it as creating your factory-ready plan ahead of schedule without committing to anything too soon.

The Bottom Line!

Sheet metal prototyping provides a low-risk, high-reward route to success, whether you are scaling an established concept or refining a new product. It doesn't require a ton of resources to get started, and it's quick and versatile. Early product success in today's market depends on agility, which sheet metal enables.

Frequently Asked Questions

Why

choose sheet metal prototyping?

Choosing sheet

metal prototyping China ensures faster turnaround, high-quality standards,

local communication, and reduced shipping delays. All of this is critical for

early-stage product testing.

What

industries benefit most from sheet metal prototyping?

Industries like aerospace, automotive, electronics,

medical devices, and robotics rely heavily on sheet metal for rapid prototyping

and durable test components.

How

does sheet metal compare to other prototyping methods?

Unlike 3D printing or injection molding, sheet metal

requires less prototyping tooling, offers better strength, and is ideal for

functional testing of end-use components.

Can

sheet metal prototypes transition into full production?

Yes. Sheet metal prototypes often serve as the

foundation for scalable manufacturing, making them ideal for bridging early

design phases with production.

Ready to accelerate your product development? Partner with Uidearp for expert sheet metal prototyping services that drive early product success.