Manufacturing success is no longer determined solely by speed. The true advantage is in how well concepts are tested before manufacturing. Plastic extrusion prototype offers manufacturers a useful means to investigate design intent, material behavior, and real-world performance without taking a chance on full-scale tooling too soon.

Why Prototyping Now Decides Market Position?

Modern manufacturing is tougher than ever. Errors spread quickly throughout supply chains, tolerance standards are higher, and product cycles are more stringent. Teams may evaluate complex features early on with plastic extrusion prototyping, long before commitments become costly or irrevocable. Instead of reactive correction, it makes space for deliberate adjustment.

Manufacturers can physically evaluate fit, flexibility, surface polish, and dimensional consistency instead of depending on digital assumptions. This practical clarity frequently highlights small design options that are missed by software simulations.

Turning Design Precision into Production Confidence

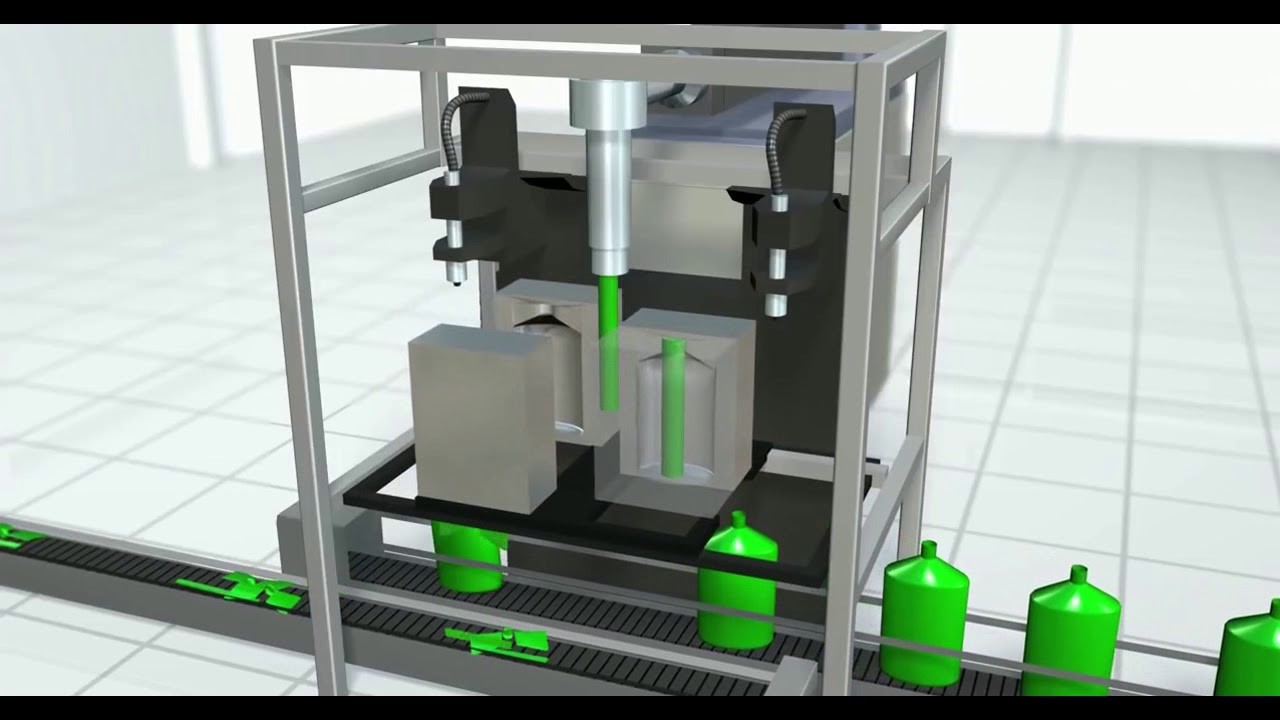

Functional roles such as sealing, directing, insulating, or shielding are often performed by extruded components. Performance can be significantly impacted by even minor profile adjustments. Engineers can better understand how materials react to actual extrusion conditions such as heat, pressure, and cooling behavior by using prototyping.

This step serves as a decision filter for manufacturers collaborating with Plastic Extrusion Prototyping China partners. Prototype-tested profiles proceed with assurance. Those that don't are improved without upsetting budgets or schedules.

Faster Learning Without Costly Commitments

Decisions are locked in too early by traditional tooling. A more adaptable route is provided via prototyping. Manufacturers can test different geometries, wall thicknesses, or materials without having to bear the cost of production dies.

The design, engineering, and production teams work together more effectively as a result of this flexibility. Discussions move from defending presumptions to enhancing results. This strategy eventually shortens redesign cycles and improves manufacturing discipline.

A Practical Edge Across Industries

Extrusion prototyping is versatile and may be used in a wide range of industries, from automotive components to medical enclosures and construction systems. Its usefulness is found in both learning quality and speed. Thoughtful prototyping by manufacturers often results in products that work consistently, behave as predicted, and require fewer downstream adjustments.

Where Smart Manufacturers Pull Ahead?

Businesses that approach prototyping as a strategic process instead of a formality frequently outperform rivals. They arrive at production with better supplier alignment, fewer surprises, and more precise requirements. Prototyping with plastic extrusion is not limited to manufacturing. It influences more intelligent production choices.

The Final Takeaway!

Today's manufacturing edge stems from clarity rather than short corners. Plastic extrusion prototyping provides a controlled setting for idea exploration, questioning, and refinement before scale magnifies every decision. Better products and more consistent growth are the silent rewards for producers who are prepared to devote early attention.

Frequently Asked Questions

How does extrusion prototyping compare

to other validation methods?

Unlike purely digital reviews, it reveals real

material behavior. When paired thoughtfully with processes like rapid injection

molding, manufacturers gain broader insight across multiple production

pathways.

What makes plastic extrusion

prototyping valuable before production?

It reduces design uncertainty and avoids expensive

tooling adjustments after production decisions are made by enabling

manufacturers to physically assess profile correctness, material reaction, and

functional performance early on.

How does plastic extrusion prototyping

improve collaboration?

It provides a common point of reference for the

engineering, production, and design teams. Compared to abstract drawings or

simulations alone, real examples promote positive dialogue, quicker consensus,

and more assured conclusions.

Is plastic extrusion prototyping

suitable for complex profiles?

Yes. Manufacturers can evaluate tolerances, surface

behavior, and structural consistency with the aid of prototyping, which is

particularly helpful for complex geometries before committing to full-scale

extrusion tooling.

Does prototyping slow down the

manufacturing timeline?

It reduces timelines in general when applied properly.

Rework later on, which frequently results in lengthier delays than the

prototyping phase itself, is avoided by early testing.