3D printing is adopted by a huge mass because it has changed the working model of many industries. It has brought the digital model into a physical three-dimensional object by adding a layer of material. There was a time when 3D printing was only applicable for prototyping and early stages of some manufacturing industries but today it has made a great place in the production technology.

The use of 3D printing is easy and cost-effective as compared to other manufacturing processes because it does not require any specific tools for cutting. It is a direct print from the machine to design a mold. Here the objects created by depositing materials in the layer based on the digital model. 3D printing works with the combination of software, hardware and materials.

The team of experts at Uidea Rapid Prototype uses the latest techniques and provides the most efficient service of 3D printing in China to the clients from different industries. We provide 3D printing service as per the requirement of the client at a competitive rate.

Generally, the processing time for 3D printing depends on the size and type of printer used which can extend to 18 hours but that is not the case. We are popular for 3D printing in China because we take minimum time to complete the printing process and give the best result. Our service quality is well accepted in the industry and we have got a great response from our clients. The 3D service provided by Uidea Rapid Prototype is not restricted due to the international borders and receives orders from worldwide.

You only have to connect with our team through the registered contact details for 3D printing in China and the rest will be our responsibility. We study the client’s requirements, plan, strategize and implement it to give the output. Till now, we have completed several successful projects and many are in pipeline. It is the trust of our clients and customers that have helped us to make a great space in the 3D printing service.

SLA 3D Printing

SLA or Stereolithography is a new and advanced additive manufacturing method based on 3D CAD, computer controlled layers scanning and rapid layer separating and accumulating principles. SLA is a process whereby a laser converts a liquid photopolymer into a solid plastic layer by layer. It is one of the major branches of recent rapid delevopling 3D printing additive manufacturing technology. This technology could produce SLA prototype in accordance with the draft design rapidly. Thus, all aspects of the product (its functions, technologies, decoration, aesthetics of appearance, feasibility of man-machine engineering) could be observed. In this way, the clients could reduce development risk through promptly feedback in an early stage.

SLA 3D Printing Machines

SLA is one of 3D printing technologies. SLA printing cost is becoming cheaper and cheaper. Uidea Rapid Prototype use a wide range of SLA materials, serving a wide range of inductries including toy, automotive, house appliances, medical device, etc. Also SLA can be used to produce the master model for making silicone rubber moulds for the vacuum casting process.

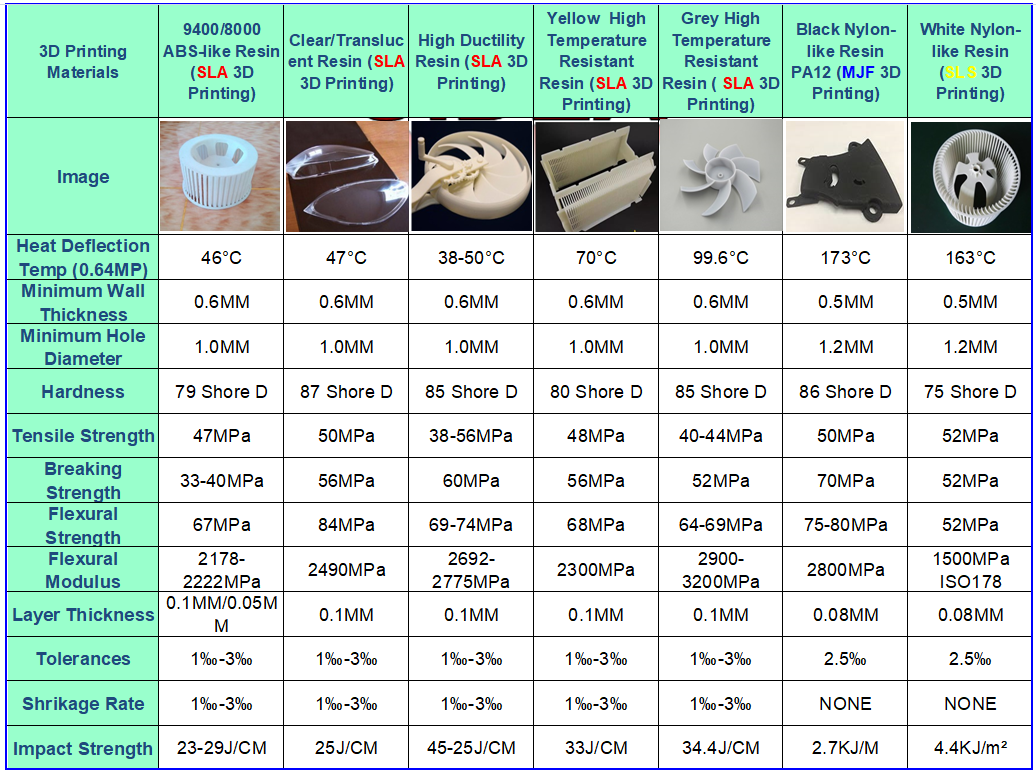

SLA, MJF, SLS 3D Printing Materials

SLM 3D Printing

Selective Laser Melting (SLM) is an advanced additive manufacturing technique that leverages the power of lasers to construct intricate three-dimensional objects, layer by layer. Unlike traditional manufacturing methods that involve subtracting material, SLM is an additive process, which means it adds material incrementally, resulting in minimal waste and exceptional design freedom.

The SLM process begins with a bed of fine metal powder. A high-powered laser selectively melts and fuses the metal particles according to a digital design, creating a solid object with exceptional precision and complexity. The layers are stacked on top of each other until the final product is formed.

SLM 3D Printing Machines

Precision: SLM offers a level of precision that is unparalleled in the world of manufacturing. It can create intricate geometries and complex structures that were previously impossible to achieve.

Strength and Durability: SLM produces components known for their exceptional strength and durability, making it ideal for applications where structural integrity is paramount.

Complexity: SLM enables the production of highly complex and integrated parts, reducing the need for assembly and reducing production time.

SLM 3D printing has made significant inroads into various industries:

Aerospace: In the aerospace sector, SLM is used to manufacture lightweight but robust components for aircraft and spacecraft. These parts are engineered to withstand extreme conditions and reduce overall weight.

Medical: SLM plays a vital role in the production of custom implants and prosthetics in the medical field, ensuring a precise fit and enhanced patient comfort.

Automotive: The automotive industry benefits from SLM by producing intricate components that enhance vehicle performance and fuel efficiency.

Tooling and Engineering: Tool and die makers rely on SLM to create molds and tools with remarkable precision and durability.

Research and Development: SLM is an invaluable tool for researchers and product developers, allowing for rapid prototyping and the testing of new concepts and designs.

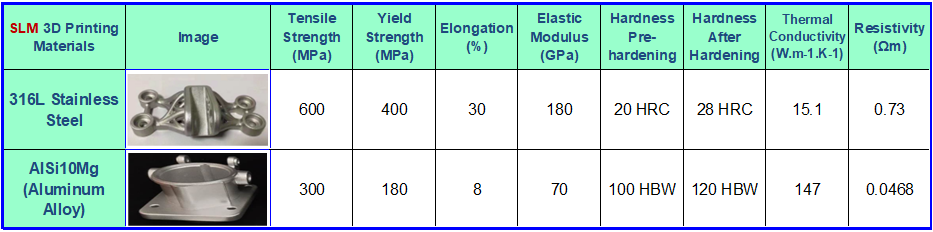

SLM 3D Printing Materials

SLS 3D Printing

Selective Laser Sintering (SLS) is a revolutionary additive manufacturing process that employs a high-powered laser to selectively heat and fuse powdered material, layer by layer, creating intricate three-dimensional objects. Unlike traditional subtractive manufacturing methods, SLS is an additive process, meaning it builds objects from the ground up, offering greater design freedom and minimal material wastage.

The SLS process commences with a bed of powdered material, typically thermoplastics, but it can also include ceramics and certain metals. The laser scans the powdered surface, fusing particles together according to a digital design, resulting in the formation of a solid object. This layer-by-layer approach allows for the creation of highly complex and functional parts with ease.

Applications of SLS 3D Printing

SLS 3D printing has made its mark in various industries:

Product Prototyping: SLS is frequently employed to create prototypes in industries ranging from consumer goods to electronics. Its ability to produce functional prototypes quickly is a valuable asset.

Dental: SLS technology finds extensive use in the dental field for creating precision dental models, crowns, bridges, and other oral prosthetics.

Aerospace: SLS is adopted in aerospace for rapid prototyping and manufacturing of lightweight, complex components that meet stringent industry standards.

Automotive: The automotive sector utilizes SLS to develop components with intricate designs, enhancing vehicle performance and aesthetic appeal.

MJF 3D Printing

Multi Jet Fusion (MJF) is an advanced additive manufacturing process that uses inkjet arrays to selectively apply fusing and detailing agents to a bed of fine powdered material, typically nylon. These agents are then fused using infrared energy, layer by layer, to create precise three-dimensional objects. This additive process is distinguished by its incredible precision, speed, and the ability to produce objects with remarkable complexity and structural integrity.

The process commences with a thin layer of powdered material being evenly distributed across the build platform. The inkjet arrays then deposit fusing and detailing agents on the powder bed, defining the shape of the object to be printed. Subsequently, the layer is exposed to infrared energy, which triggers the fusion of the powdered material at the specified points. The cycle is repeated until the final object is constructed, layer upon layer.

Applications of MJF 3D Printing

MJF 3D printing has made substantial inroads into a wide array of industries:

Prototyping and Product Development: MJF is a preferred choice for rapid prototyping and iterative product development, allowing for quick design validation and refinement.

Custom Manufacturing: Industries such as healthcare utilize MJF for creating custom orthopedic implants and prosthetics, offering patients a personalized fit and enhanced comfort.

Aerospace: The aerospace sector benefits from MJF by manufacturing lightweight, high-strength components for aircraft and spacecraft, contributing to fuel efficiency and performance.

Automotive: MJF technology is leveraged to design and produce complex automotive components, enhancing vehicle aesthetics and functionality.

Consumer Goods: From personalized fashion items to unique consumer products, MJF enables the creation of customized, high-quality goods.

MJF 3D Printing Machines

SLA Printing Prototype

SLA Printing Prototype

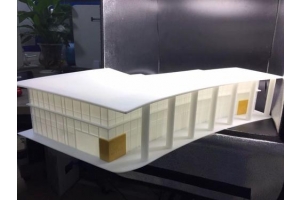

SLA 3D Printed Architecture Model

SLA 3D Printed Architecture Model

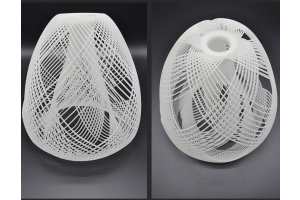

Complicated SLA 3D Printing Part

Complicated SLA 3D Printing Part

SLA 3D Printed Architecture Model

SLA 3D Printed Architecture Model

SLA 3D Printing Toy Prototype

SLA 3D Printing Toy Prototype

SLA 3D Printing Clear Parts

SLA 3D Printing Clear Parts

3D Printing Cartoon Figure

3D Printing Cartoon Figure

3D Printing Cartoon Figure

3D Printing Cartoon Figure

SLM 3D Printed SLM Aluminum Parts

SLM 3D Printed SLM Aluminum Parts

SLM 3D Printed Stainless Steel Component

SLM 3D Printed Stainless Steel Component

SLS 3D Printed Parts

SLS 3D Printed Parts

MJF 3D Printed Part

MJF 3D Printed Part