Vacuum Casting or Urethane Casting or Duplicating (called in local China prototype circle) is one of the major reliable rapid prototyping methods for making dozens of high quality prototypes which can be used for structure checking, trade shows or presentations.

Uidea Rapid Prototype China Co., Ltd. is equipped with 3 vacuum casting machines with capability of handling maximum size of 1200 X 1000 X 1000 mm. For vacuum casting, first, we need make a master model by SLA or CNC, then apply whatever surface finishing to the master model. We then pour liquid silicone rubber around the master model in casting box. Once cured, we cut out the silicone rubber mould with which we cast up to 20 PU (polyurethanes) parts per silicone mould in a vacuum casting machine.

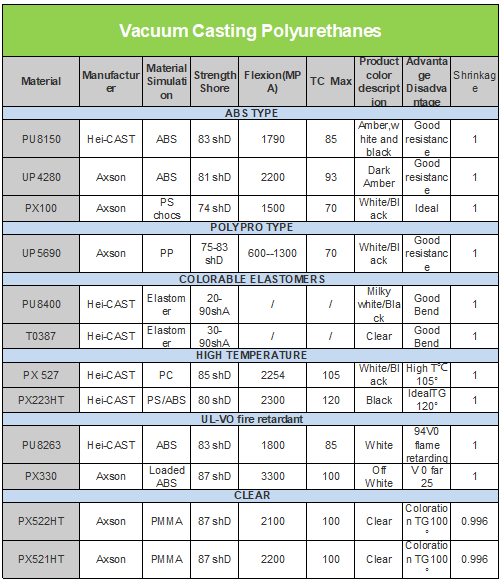

Vacuum Casting Materials

Vacuum casting is relatively labor intensive and typically requires between 2 and 5 days to produce the first casted product. The technology is best suited to low volume productions.

The PU which most China prototype companies are using including domestic PU, imported UP4280 which is a most popular ABS simulant, PX522HT which is best for clear parts; UP8400 is our rubber simulant. All can be colored to any Pantone number.

Vacuum Casting Machine

Vacuum Casting Machine

Vacuum Casted Overmolding Products

Vacuum Casted Overmolding Products

Vacuum Casted Clear Parts

Vacuum Casted Clear Parts

Silicone Mould and Casted Product

Silicone Mould and Casted Product