In today's competitive environment, successful product development depends on speed and accuracy. For engineers, product designers, and innovators looking to swiftly transform ideas into physical models, rapid prototyping services have emerged as an essential tool. Whether you’re building a tech gadget, an automotive component, or a medical device, choosing the right prototyping partner is crucial. Poor product quality, mistaken expectations, and expensive delays might result from picking the incorrect supplier. This blog provides a thorough checklist to assist you in selecting a trustworthy and capable rapid prototyping partner.

Evaluate Technical Capabilities

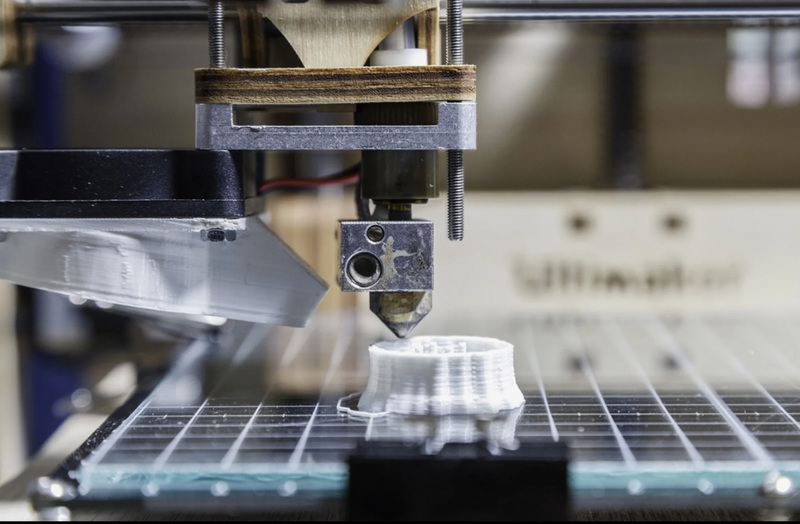

Start by evaluating the provider's technical proficiency. Examine their precise standards, supporting technologies (such as CNC, SLA, SLS, FDM, etc.), and accessible materials. A business with a wide variety of tools can better meet your unique requirements and provide the best production paths depending on complexity and goal.

Check Industry Experience

Suppliers with experience in fields such as electronics, medical devices, automotive, or aerospace provide important perspectives on industry compliance, tolerances, and material compatibility. Experienced partners may help you navigate the design-to-prototype process more effectively and minimize design execution mistakes.

Review Past Projects and Client Feedback

Client testimonials, portfolios, and case studies may all give valuable insight into a provider's success. Look for businesses with a track record of on-time delivery and superior results. B2B platforms and internet reviews may also provide unbiased feedback to support their legitimacy.

Consider Turnaround Time and Flexibility

The main focus of rapid prototyping services is rapid delivery. Ask about manufacturing timelines, lead periods, and their approach to last-minute design revisions. During the R&D stage, a service provider who is responsive and adapts quickly to changes is a great advantage.

Assess Communication and Support

Effective communication is essential! Thus, select a company that provides committed account management and direct technical assistance. Confusion may be greatly decreased and the result improved with frequent updates, prompt replies, and thorough explanations throughout the process.

Final Words

Comparing costs is only one aspect of selecting the best partner for rapid prototyping services. It all comes down to locating a technically proficient, reliable, and flexible workforce that shares your manufacturing objectives for mold in China. You may approach your selection process with clarity and confidence if you use this checklist.

FAQs

How can I tell whether a supplier is trustworthy?

To check their trustworthiness, look at their portfolio, read client reviews, and request references.

Which sectors gain the most from rapid prototyping?

Prototyping is used by sectors such as consumer electronics, automobiles, medical devices, and aerospace to validate designs and market products more quickly.

What is the average turnaround time for a rapid prototype?

Depending on intricacy and material availability, several vendors provide lead periods ranging from two to seven days, while turnaround times vary.

Ready to bring your ideas to life? Partner with Uidea for expert rapid prototyping services tailored to your needs.