One crucial question pulses in the background as soon as you sketch your idea on paper: Will anyone really use this? Answering this question on its own might be the difference between quiet obsolescence and exuberant enthusiasm for a startup. Rapid prototyping can help with that, and its effects are even more powerful when combined with smart manufacturing in nations like China.

Validating Ideas at the Speed of Thought

When you construct something fully only to realize it doesn’t resonate, you have lost money, effort and momentum. Rather, you may get input from actual consumers by developing a prototype early on. Rapid prototyping enables you to test hypotheses with less financial outlay, enabling faster iteration and better alignment with market demands.

However, startups require a prototype that replicates real-world use and shows the appearance, feel, and functionality. This entails going from low-fidelity mock-ups to something that is nearly ready for production. This is where rapid prototype China partners excel.

Why a Startup Might Choose Rapid Prototype China & Injection Molding China?

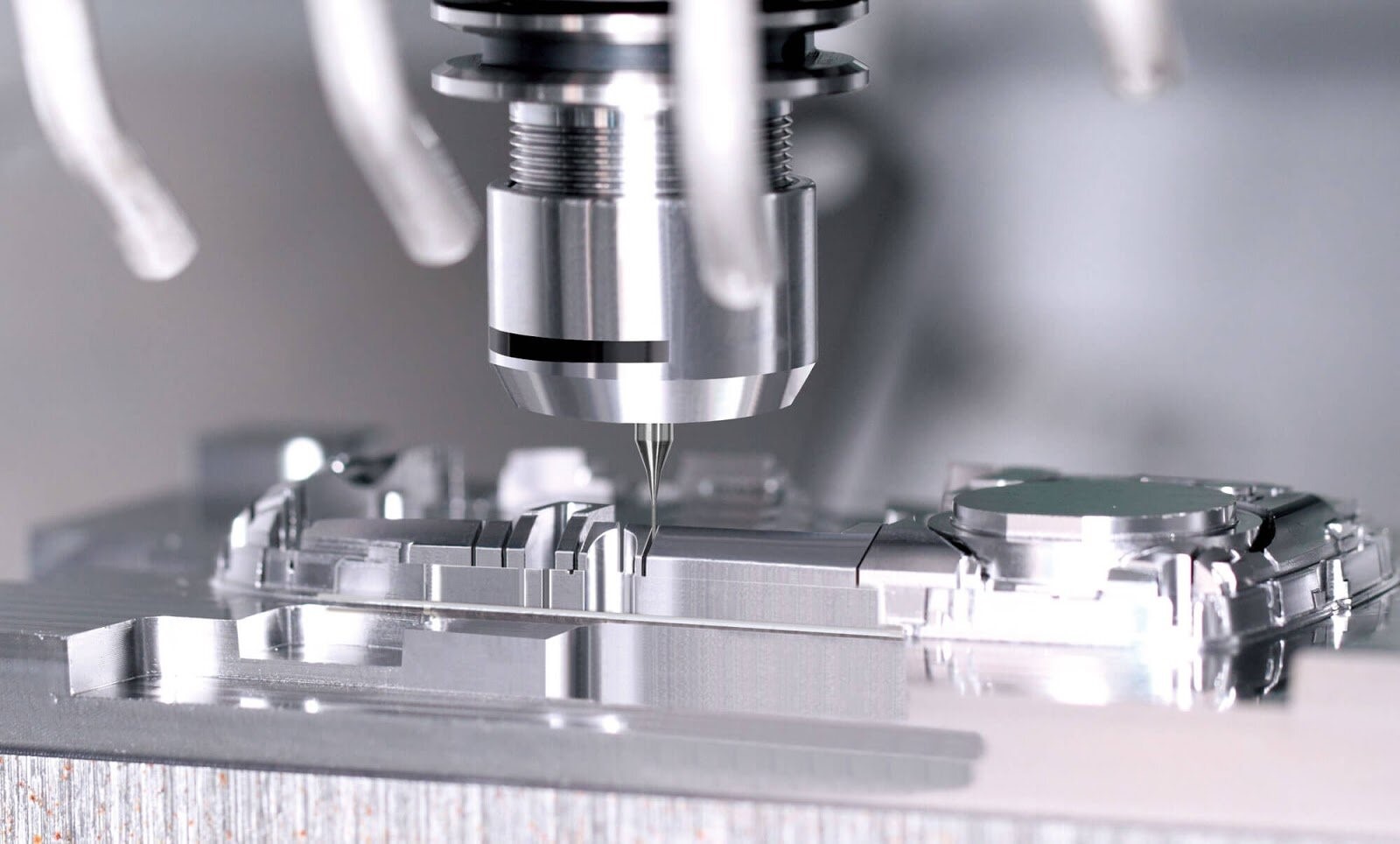

Imagine that once you have perfected your shape and locked in your fundamental function, you want to confirm it in conditions that are closer to mass. China offers sophisticated prototyping and tooling at significantly lower costs and shorter lead times. For instance, businesses in China provide low-volume injection molding, vacuum casting, rapid prototyping with precision CNC machining, and more.

Similarly, "injection molding China" services, which enable low-volume runs, quicker mold iterations, and economical testing of manufacturing readiness, are closely linked to ramping into small-batch production via injection molding.

Risk, Cost and Speed, Handled Wisely

Three challenges confront startups: squandering money, taking a long time to market, and launching something that no one wants. Rapid prototyping mitigates all three. Prototypes can save costly late-stage revisions, uncover hidden problems early, and improve user flows.

You can achieve faster lead times, cheaper costs per iteration, and access to production-level tooling alternatives with rapid prototyping, all without completely committing to full-scale tooling before you are sure you are headed in the right direction.

Bringing It All Together

Momentum is your most valuable asset as a startup. You lose money, weaken your brand, and give rivals an opportunity if you act slowly. You can make wiser wagers more quickly with rapid prototyping and bridging into injection-molding readiness. You go from an optimistic notion to a proven product when you can hold a near-final version in your hand, present it to users, test manufacturing, make adjustments, and finally commit.

Final Takeaway!

Perfection is not as important in the startup industry as speed and validation. Adopting rapid prototypes and working with flexible production partners gives you the opportunity to change course early, focus on what really matters, and provide something that appeals. More than simply a procedure, it’s a mindset: test early, refine rapidly, manufacture smart. Your concept could be amazing, but only if it is properly validated.

Frequently Asked Questions

When

should a startup consider “injection molding China”?

Once your prototype has shown user interest and design

maturity, injection moulding China becomes relevant for low-volume production

or bridge tooling, letting you test production logistics and cost without full

mass-tooling commitment.

Is

rapid prototyping always cheaper than full production tooling?

Yes, basically. Large investments and lengthy lead

periods are required for building full-scale tooling. Smaller-scale testing,

faster feedback loops, and less expensive errors before committing are all made

possible by rapid prototyping.

What

do I need to look out for when outsourcing prototyping/manufacturing to China?

Look for clear specifications, communication clarity,

quality control procedures, tooling cost transparency, and logistics to prevent

surprises.

How

does rapid prototyping improve investor or customer presentations?

A startup may provide a physical prototype, something

that users can touch, engage with, or test instead of PowerPoint.