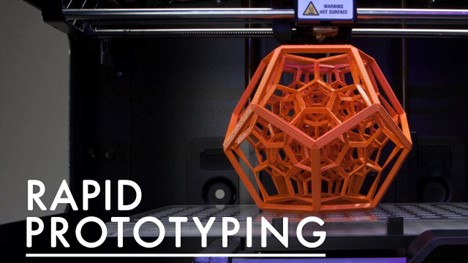

Turning ideas into reality faster than ever.

If you are in an electronics store, the gadgets you are seeing might have been an idea a week ago. This is the power of prototyping! In the rapidly evolving field of consumer electronics, rapid prototyping services help to close the gap between creativity and manufacturing. It is the process of quickly producing models or components in order to evaluate their usability, design, and functioning before full-scale production.

Are you curious about how it turns your concepts into functional, practical products so quickly? Read till the end to uncover this intriguing journey from idea to creation.

The Spark: Turning Ideas into Tangible Designs

Every electronic product starts as an idea, which might be a sketch or just a concept. Rapid prototyping uses sophisticated 3D printing and digital design techniques to turn these ideas into tangible models. With this, designers are able to test, improve, and verify their ideas without having to wait weeks for tooling. It allows consumer electronics firms to have faster development cycles, reduced costs, and the opportunity to identify design faults early, before investing in mass production.

Precision is Everything: The Role of Prototype Tooling

When the design is complete, it's time to bring it to life. Prototype tooling is essential in this situation. It allows manufacturers to use materials that are similar to those used in final manufacturing to create precise components. This phase makes sure the prototype feels and works like the actual product, in addition to having the right appearance.

Testing the Limits: Functionality and User Experience

A good design is successful when it performs well. Rapid prototyping allows engineers to test:

Durability: The device's capacity to tolerate drops or stress.

Ergonomics: Whether the dimensions and form are appropriate for daily use.

Performance: The way parts work together and react in practical settings.

By identifying weak spots early on, testing helps save expensive reworks during mass production, acting as a safety net for all innovative brands.

Speed Meets Innovation: Because Time Matters

Being first to market can define success in consumer electronics. Rapid prototyping drastically reduces lead times, which speeds up product development. Once taking months, the procedure now takes days. This enables companies to continually develop, incorporate customer feedback sooner, and react to market changes more quickly. Time saved here directly translates into a competitive advantage for both new and existing businesses.

From Prototype to Production: The Final Step

The prototype is prepared for production as soon as it passes testing. The final production process is guided by the insights obtained from the prototype stage, guaranteeing effectiveness and quality. Rapid prototyping doesn't end with the model; it helps businesses provide high-performing, visually pleasing products to customers by laying the groundwork for scalable, dependable manufacturing.

Key Takeaways

Rapid prototyping services transform the design and construction of consumer electronics from idea sketches to finished goods. It gives creators the confidence to manufacture, test, and develop without fear. Rapid prototyping transforms ideas into reality and ambiguity into accuracy, whether you're creating the next big wearable or smart product. Moreover, manufacturers guarantee that every design transitions flawlessly from concept to creation with unparalleled precision by integrating prototype tooling into the process.

FAQs

What is rapid prototyping?

It's a method of rapidly making models or parts with 3D printing and other technologies to verify design and performance prior to manufacturing.

What's the importance of rapid prototyping in electronics?

This reduces development time, highlights design faults early, and generates well-designed, high-grade final products.

What does prototype tooling contribute to product design?

It creates realistic prototypes with finish and material matching final products, facilitating performance testing and precise design proof.

Can low-volume manufacturing be carried out utilizing rapid prototyping?

Yes, it can be used in limited production lots, pilot manufacturing, and pre-market market feedback among manufacturers.

What industries take advantage of rapid prototyping?

Other than electronics, industries like automotive, aviation, healthcare, and consumer goods opt for rapid prototyping for developing innovative and precise products.