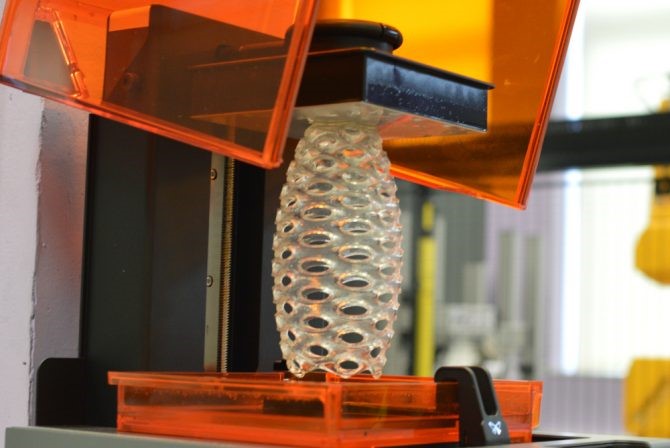

Stereolithography (SLA) 3D printing is a commercialized 3D printing technology used for producing visual prototypes across industries. It is gaining popularity over other 3D printing technologies because of the very smooth surface and very fine details you can get from a range of thermoset materials. SLA uses a computer-controlled moving ultraviolet laser beam using CAM/CAD software to precisely cure photopolymer cross-sections and print 3D objects. This process is used to create concept models, rapid prototypes, and complex assembly parts with geometric precision and accuracy in as fast as one day.

SLA 3D printers are used in a range of industries from manufacturing to product design, and engineering. If you are looking for highly detailed prototypes with tight tolerances and smooth surfaces to design patterns, molds, and assembly parts, SLA 3D printing services is a great option for you. From Automobile to jewelry, dentistry, education, and model making, the SLA 3D printing process is your way to go. Products designed using this process have the following properties:

· Rigid properties with similar aesthetics

· Tough and Durable

· Clear products for polycarbonate-like parts

· Easily castable for many industrial applications

· Exceptional performance under extreme conditions such as high temperature

SLA 3D printing process has many benefits for industrial manufacturing, product design, and prototyping. Some of them include:

· Unmatched Accuracy and Precision

SLA 3D printing process delivers highly detailed, precise, and accurate designs for a range of industrial applications. You can print 3D objects with just a few mm in size and go up to print one-meter-long parts. Everything can be achieved with exceptional resolution and accuracy from end to end.

· High Production Quality

SLA 3D printers and technologies gave evolved over the years with significant improvements in production quality. Modern SLA 3D printers offer exceptional part quality without compromising production speed or details throughout the production process.

· Increased Productivity

The highest productivity is possible with SLA 3d printing with the fastest print technology available today in the market. It can be utilized in industries where very large production runs are required. Quick interchangeable modules and processes ensure advanced manufacturing flow to increase productivity.

· Broad Choice of Materials

SLA 3D printing utilizes a wider range of materials to print 3D objects for different applications across industries. Different materials offer different finishes and characteristics for specific purposes.

SLA Applications

SLA 3D printing is the top choice for applications where precision and smoothest surface finish are your top priority. Some of the most common SLA industrial applications include:

· Master patterns for vacuum casting

· Sacrificial patterns for metal casting tools, molds, and dies casting

· Functional prototypes and assembly parts casting

· Jewelry-specific casting

· Dental models' production

When you look for 3D printing for your industrial applications, SLA 3D printing is a great option. At Uidea, we use the latest techniques and processes to offer the most efficient and affordable service of 3D printing in China to serve clients from different industries. Contacts us for 3D printing services as per your specific industrial requirements.