Rapid prototyping is an early stage in the product development process that focuses on the initial design of a product before mass production. During the prototyping process, a team of designers and engineers is primarily concerned with testing the products’ design, form, fit, and functionality. Rapid prototyping can assist you in getting your product to market faster than your competitors. It also allows you to make changes to the design, shape, size, materials, assembly, color, manufacturability, and strength to get a final product of the highest quality.

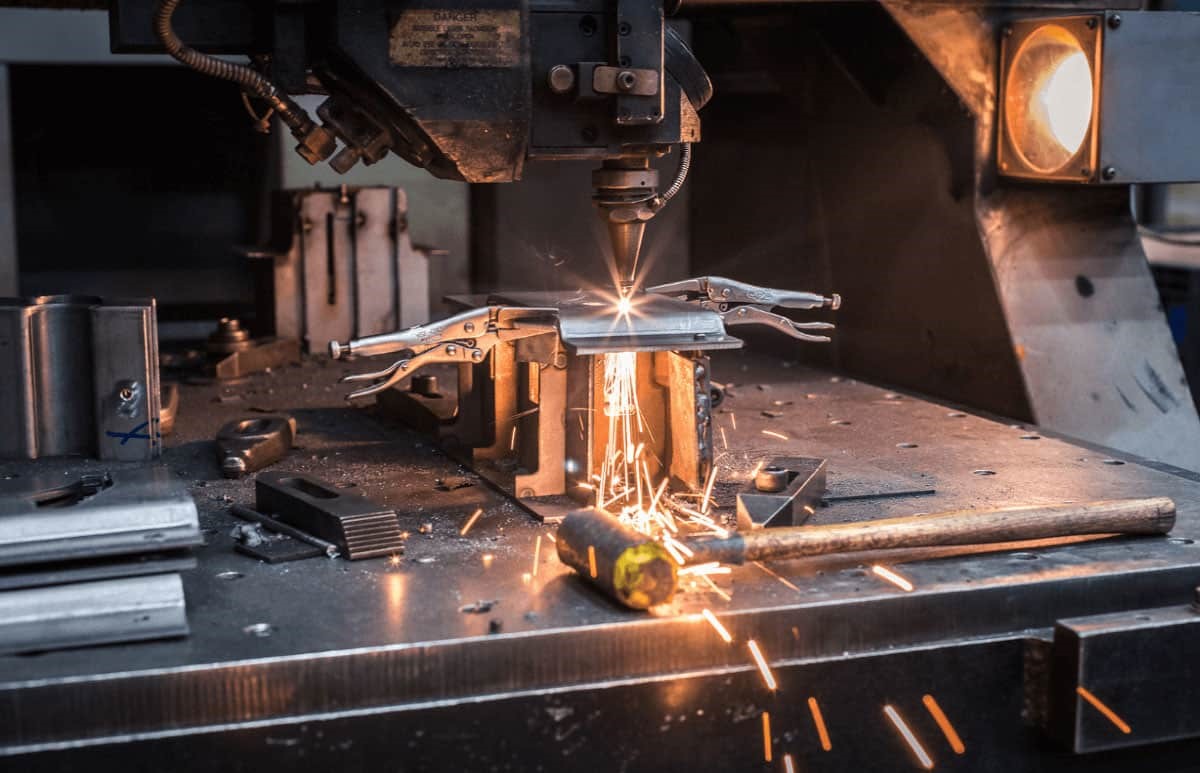

Rapid prototyping services use various manufacturing techniques to quickly create a physical part directly from its CAD model data. It can be used for manufacturing any component or sub-component during the product development process to meet specific industrial requirements. To achieve the desired product design, the design team repeat the prototyping process numerous times through the product design process using test data.

Importance of Rapid Prototyping in the Product Development Process

Companies must develop and launch new products more quickly in order to compete in today's fast-paced consumer market without compromising the quality. Rapid prototyping has emerged as the most important component of the new product development process to achieve faster product design and development, which is essential to a company’s success. Rapid prototyping accomplishes the following goals.

· Rapid prototyping enables faster product design and development, which is critical in the process of developing successful products quicker than usual.

· It allows early-stage design/concept review, testing, and validation to achieve the desired form, fit, and function of the product.

· Rapid prototyping also enables final stage product validation against market standards and technical requirements to achieve end-user satisfaction and business objective.

· It enables functionality testing against real-world situations to validate the design concept and finalize the product specification.

· Prototyping enables the scope for hands-on user experience through user participants for end-users, test engineers, and clients to obtain feedback and improve design concepts.

· It reduces costs because design teams do not need to invest in tooling or manufacturing processes that would be required for a production run of parts.

· Prototypes can be created in a variety of ways. It helps product designers try different prototyping processes to determine which method or technology is best for their specific application.

· Pre-production prototyping gives the capability to assess human factors and ergonomics to eliminate or reduce risks during and after production.

Prototype models assist design teams in making more informed decisions by obtaining valuable feedback data from prototype performance and user experience. Rapid prototyping services are used for a variety of industrial applications such as making concept models, visual prototypes, functional prototypes, pre-production prototypes, production tools, and moulds. Contact us at Uidea to know more about rapid prototyping and discuss your specific requirements.