Launching a

new product in a market involves a complex process of design, market research,

and manufacturing. In the manufacturing world, a prototype is a mock-up or

rough draft of a part. Prototypes are built before manufacturing starts,

allowing designers to test and develop the part. The prototype can be made from

the same material as the final product, or an alternative can be used for test

purposes.

Metal prototyping in

China is essential for businesses in many industries, from aerospace to

electronics. Here we’ll discuss the significance of metal prototypes and

effective methods for creating metal prototypes.

Metal

Prototypes are made using a metal manufacturing technique. Although metal is

typically used for pre-production prototypes, it can be used for early-stage

prototypes. There are several benefits of such prototypes, such as:

· Better mechanical performance

· More accurate testing

· Better aesthetics

· Higher chance of investor interest

· Easier to move to production

What method should

you choose for your metal prototypes?

Due to their

quantity, geometry, and tolerance, some metal prototypes suit only one

manufacturing process, such as 3D printing. However, most parts can be made

using a wide range of separate methods. Let’s find out which method can keep

the costs and manufacturing time to a minimum and achieve the best mechanical

results.

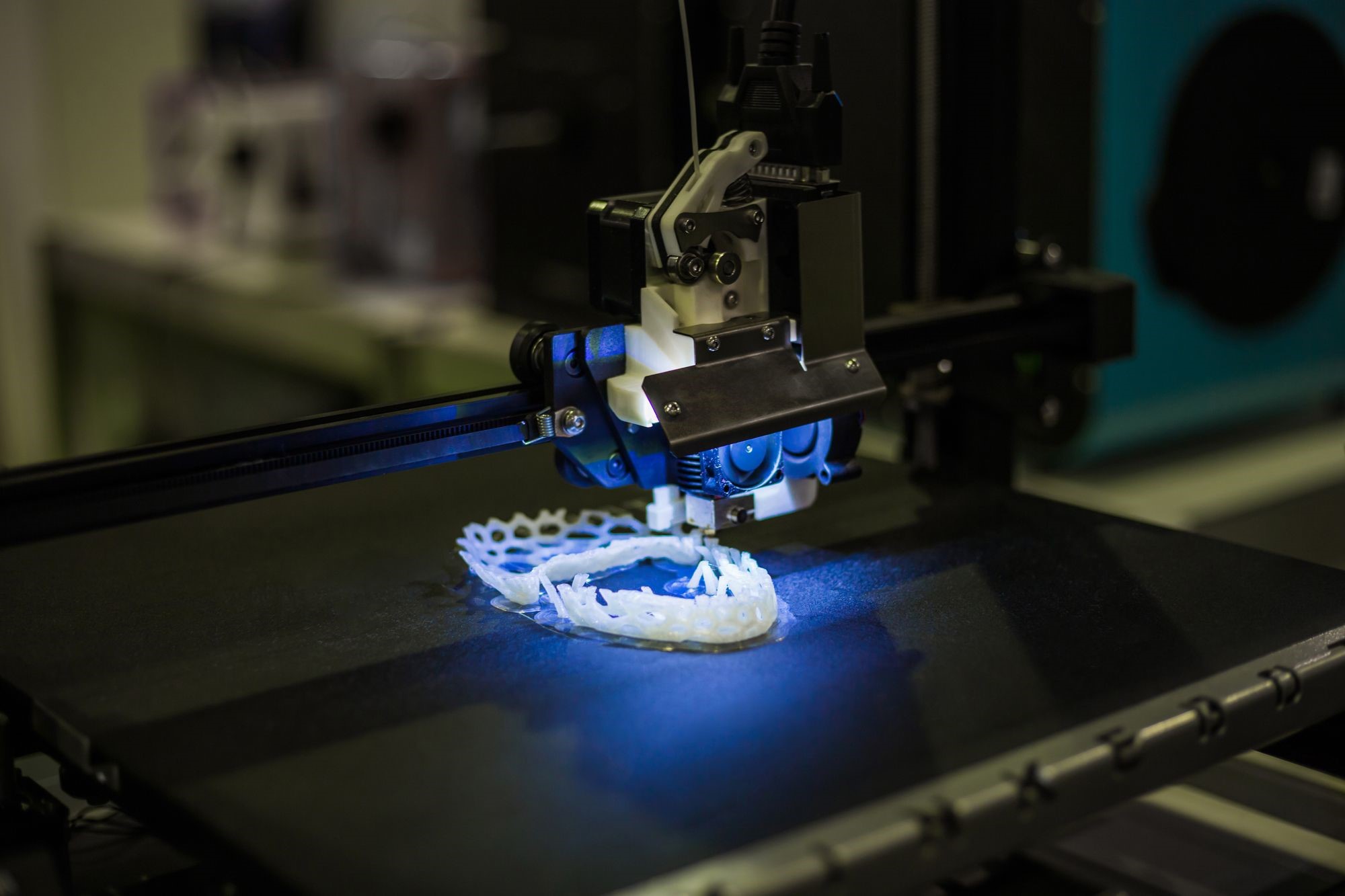

1. 3D Printing Prototypes

3D printing is a cost-effective way to create metal prototypes. 3D printing uses digital designs as input, allowing for quick changes to the design. But, the major advantage of metal 3D printing is geometrical flexibility.

Metal 3D printing prototypes may have complex features since they are built layer by layer and not cut away from a solid block.

2. CNC Machining Prototypes

CNC machining is also an affordable means of creating metal prototypes because they require no tooling. A CNC machine can precisely remove sections of material from a metal block as it uses computer instructions to guide a metal cutting tool.

CNC Machining is a practical prototyping tool because digital CAD designs can be changed in between prototypes, resulting in an efficient workflow. It is also convenient to make duplicates or distribute the designs.

3. Sheet Metal Prototyping

Sheet metal fabrication is a process that involves cutting, deformation, and assembly of sheets of metal. In a sheet metal project, it is better to design the prototype using the same techniques that will be used in production run.

Sheet metal forming process includes bending, spinning, welding, punching, and laser cutting. Sheet metal prototypes are robust and of high-quality. However, it is a bit expensive than its counterparts.

This prototype is useful if several copies of the prototypes are required.

4. Extrusion Prototypes

Metal extrusion is not usually considered a prototyping process. Most

extrusion companies deal with only high-volume production orders. But it is

worth to use metal extrusion for metal prototyping.

Extrusion is

carried out on aluminum alloys and is an apt process for simple parts like

joints and metal bars. The process is best for testing and pre-production

prototypes, where the extrusion metal prototype resembles the final parts.

Several

methods are available today for metal prototyping to innovators and engineers,

and each method has its own pros and cons. So, make sure to choose an ideal

partner for your project of metal prototyping in China.