3D printing is a process of

manufacturing a three-dimensional solid object or assembly part from a digital

3D CAD model. It is an additive manufacturing process where an object is

created by depositing, laying down, or solidifying successive layers of material

to transform a digital file into a 3D object under a computer-controlled

process. Different technologies and methods such as material extrusion, vat

polymerization, bed fusion, and Stereolithography are used for 3D

Printing.

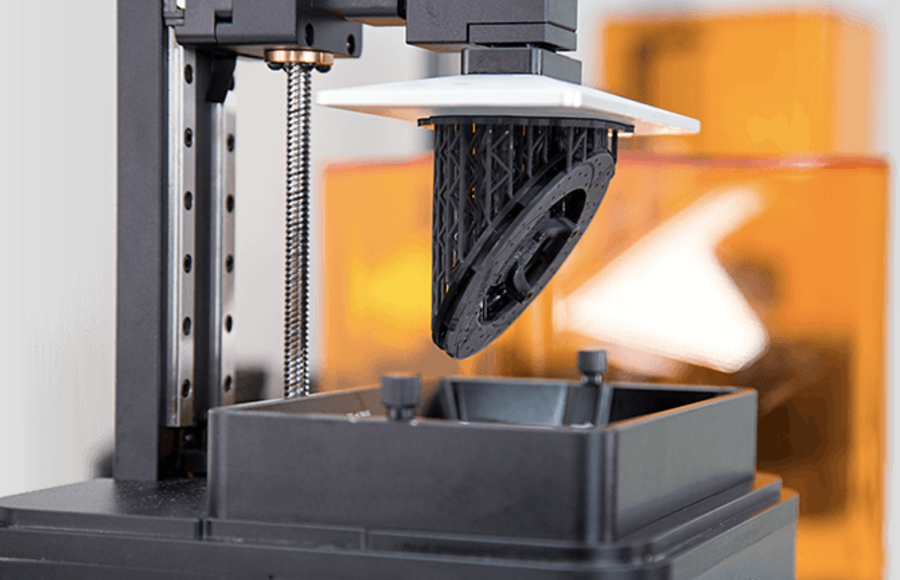

Stereolithography or SLA

3D printing is one of the most advanced and accurate printing processes to create

three-dimensional objects using digital CAD files. It is an additive

manufacturing technique that uses a high-powered laser to harden liquid

photopolymer resin to form a desired solid shape. As a widely recognized

industrial 3D printing process, SLA 3D printing is used to manufacture complex

models, assembly parts, and prototypes with high accuracy and excellent surface

finish.

How

does it work?

The basic components of an

SLA 3D printer include a tank filled with the photopolymer resin, a perforated

platform, an ultraviolet laser, and a computer interface to complete the whole

process. The SLA 3D printing workflow combines the three basic processes –

design, printing, and post-process to create a physical object.

Design:

In any additive

manufacturing process, 3D designing is the first step using CAD software. A CAD

engineer or 3D designer incorporates every detail, measurement, and

specification as per the requirements to design a 3D model in the digital

format. After designing the concept using CAD software, the CAD files are

exported in a 3D printable digital file (STL or OBJ file).

STL (standard tessellation/triangle language) files are the most preferred digital file formats for 3D object printing. STL digital files every detail of the object such as the geometry of the 3D object and other required attributes.

SLA

3D Printing:

A standard SLA printer

includes a3D slider software to configure the pre-printing settings to feed an

STL file for generating G-code language for 3D printers. It is an important

step to slice the digital model into layers for additive printing. Once the

initial settings and setups are completed, the printing software sends the

instruction to the SLA printer to begin the layered printing process.

The high-powered lasers in

the 3D printer solidify each layer of the digital model using the photopolymer

resin until the whole object is created. The laser solidifies the liquid resin

where it hits as per the uploaded design into the software. A computer

interface controls and manages the laser to design the appropriate coordinates

as per the digital feed.

Post-processing:

Once the 3D printing

process is completed, any uncured or excess resin is removed from the object

surface using isopropyl alcohol. Post-curing is the next step that enables the

object to achieve the highest possible accuracy, strength, and stability.

Post-processing also involves some additional steps depending on the material

type and part to get a high surface finish as per the industrial requirements.

So, this is how the SLA 3D

printing process is done that requires a high level of skill, knowledge, and

expertise at all levels to create a highly accurate and high finish object. If

you are looking for Industrial additive manufacturing, you should look for a

reputed and experienced company that has expertise in SLA

3D printing in China for your applications.

A professional and

qualified team can help you out with your 3D designs and feeds to get the right

settings for 3D printing your industrial applications. They ensure to meet your

expectations with every little detail right from designing to post-processing

to achieve the best results.