CNC technology has come a long way since its inception in the 1940s. It is being used in various industries to manufacture prototype tools and machinery parts on a large scale. It allows the manufacturer to create as many copies as required using different types of material. It works on a technical program to manufacture plaques, carved signs, decorations, car parts, etc.

The transportation industry needs CNC machines to construct parts with the exact specification and utmost accuracy. The CNC machines are widely used, for the construction of parts to be installed in various vehicles, including shipping vessels, freight trains, passenger rail, 18-wheel transport trucks, and passenger vehicles.

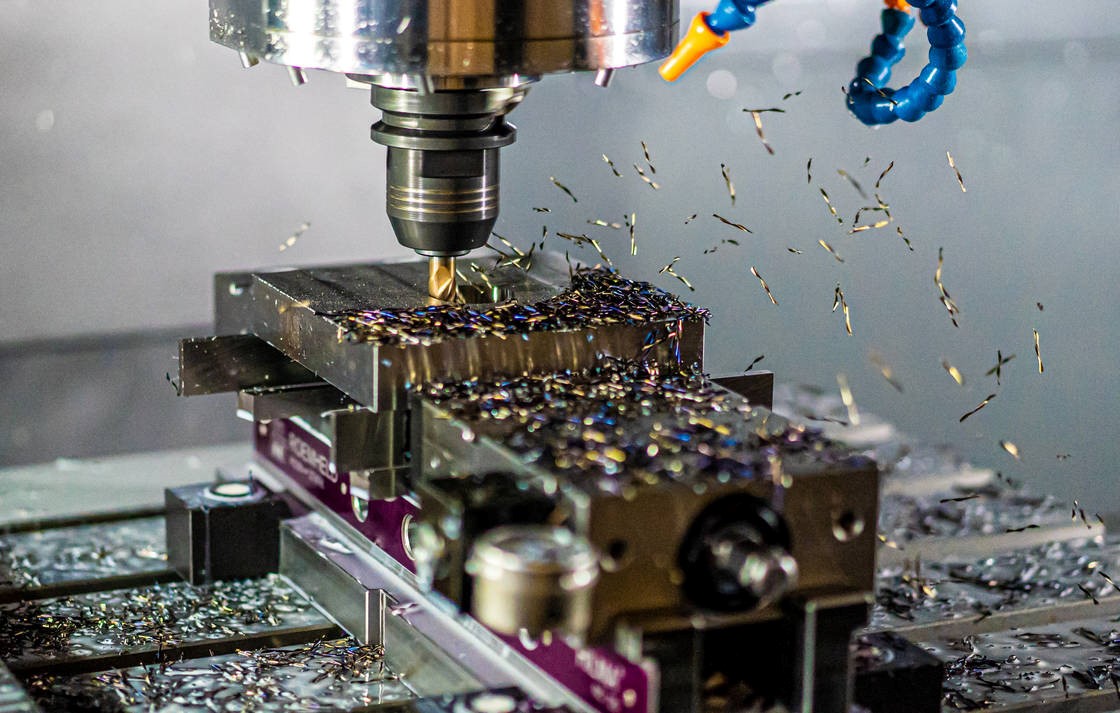

It has proved to be a technical marvel in the manufacturing industry, leading to its rapid growth. It is almost impossible for manual machines to keep up with the technological advancement of CNC machining services in pace and accuracy. The transport industry is famous for its high manufacturing rate, and CNC machining services have been a significant contributing factor to its growth. Let’s discuss the advantages of CNC machining services to understand its contribution better.

Benefits of CNC machining services

Automation

CNC machines can be programmed for continuous production of a specific part for 24hours a day without taking any breaks. The machine does not need constant supervision, which contributes to the reduction in labor costs. The machine’s automation aspect can be increased by the installation of robotic arms to remove the finished product out of the CNC machine and load more material. A technician will only be required in case of any technical faults.

Precision and accuracy

The CNC machine is designed to create accurate replicas of various parts that improve the efficiency and reliability of vehicles. Any minor deviation in the constructed parts can lead to potential damage. The CNC machine produces parts as per the exact specifications set by the engineer. It ensures the production of top-quality parts. The parts constructed for installation in vehicles in a mass-production setting ensures the same experience for all customers owing to them being identical.

Speed

The machines are designed to create parts with high accuracy and rapid speed, which is impossible to achieve with human hands. The speed in the production of parts provided by CNC machines is the major contributor to the rapid growth of the transportation industry. The only factors affecting the production speed of CNC machines are the material used and the complexity of the part.

The parts produced using CNC machinery for the transportation industry

Vehicles are constructed using a wide range of components, created using various manufacturing processes, including casting, injection molding, and vacuum forming. The major automotive parts produced using CNC machines include shafts, valve retainers, engine blocks, pistons, timing covers, bushing, transmission cases, gears, brake systems, and secondary machining operations on castings. This long list of components mentioned here is just an overview of the wide range of parts that can be produced with CNC machinery.

Choose the best CNC machining services for your future manufacturing projects.