Sheet metal prototyping gives teams a fast, low-risk way to validate design, materials, and manufacturability before placing big bets. By locking specs early and building pilot runs with common gauges and finishes, companies shorten lead time, avoid rework, and keep multiple suppliers ready to step in.

Businesses constantly struggle to strike a balance between speed, cost, and reliability in the highly competitive manufacturing environment of today. Sheet metal prototyping is an underutilized approach that aids businesses in resolving these issues. In addition to serving as a tool for design validation, it is essential for bolstering supply chains and mitigating risks that would otherwise result in expensive setbacks.

Faster Product Validation

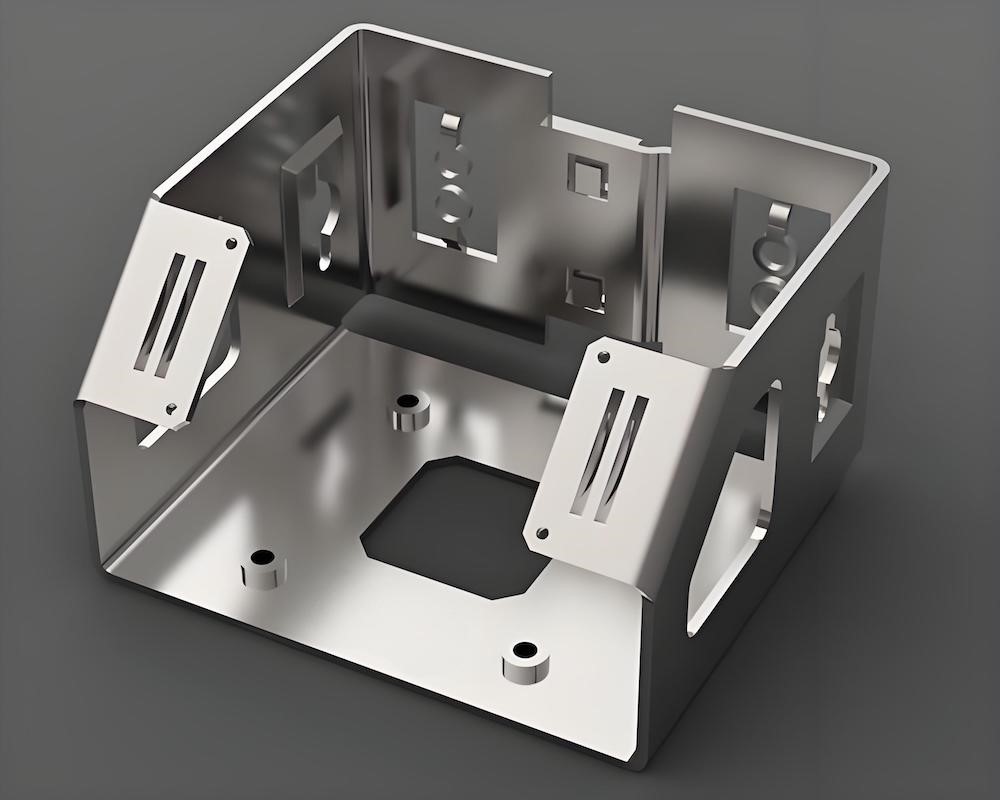

Manufacturers often experience delays when introducing new product designs because of design defects that only become apparent during production. Companies can test designs early, improve functionality, and fix issues with sheet metal prototyping before large-scale manufacturing starts. Businesses can prevent material waste, production halts, and shipping delays by identifying these issues early.

Improved Flexibility in Manufacturing

Timelines can be severely impacted by supply chain interruptions, whether they are brought on by supplier dependence, transit problems, or worldwide shortages. Sheet metal prototypes give businesses the ability to swiftly change designs and, if needed, switch to different materials or manufacturing techniques. Continuity is guaranteed by this flexibility even in the event of external supply chain issues.

Enhancing Supplier Collaboration

Engineers, designers, and suppliers can communicate more effectively thanks to sheet metal prototyping. Conversations about scalability and manufacturability become less theoretical and more realistic when tangible prototypes are available. This mutual knowledge lowers the possibility of expensive rework, guarantees supplier alignment, and decreases manufacturing errors.

Cost-Efficiency and Risk Mitigation

There are financial risks associated with any disruption in the supply chain. Businesses significantly reduce the likelihood of mass production issues, defective parts, and shipment rejections by integrating sheet metal prototypes into the product development cycle. Prototyping costs a lot less up front than the losses brought on by supply chain breakdowns.

Future-Ready Manufacturing

Sheet metal prototyping serves as a link between design software and actual production as industries shift to digital and flexible manufacturing. It makes supply chains stronger and less susceptible to disruption by lowering uncertainty, fostering resilience, and guaranteeing that businesses can react quickly to market needs.

In summary, sheet metal prototyping is an effective method for lowering supply chain risks and is not only a tool for designers. It enables companies to handle unforeseen obstacles while upholding promises for product quality and delivery by guaranteeing precision, adaptability, and cooperation. Moreover, when combined with successful outsourcing, like plastic mould China, producers are able to achieve the ideal balance between cost-effectiveness and risk mitigation.

Frequently Asked Questions

How

does sheet metal prototyping reduce supply chain risks?

Sheet metal prototyping identifies design flaws early,

minimizes mass production errors, and allows manufacturers to adapt quickly to

material or supplier changes. This reduces reliance on unstable supply chains

and enhances overall production stability.

Why

is flexibility important in supply chain management?

Flexibility allows manufacturers to adjust to

unexpected disruptions such as raw material shortages, logistics delays, or

regulatory changes. Sheet metal prototyping supports this adaptability by

ensuring designs can be modified quickly without derailing production

schedules.

Can

local sheet metal prototyping reduce dependency on overseas suppliers?

Yes. By validating prototypes locally, companies

create backup production options closer to target markets. However, global

partnerships, like outsourcing with plastic

mould china, can still help reduce costs while maintaining supply chain

balance.

How

does prototyping improve collaboration with suppliers?

Prototyping provides tangible samples for engineers

and suppliers to analyze. This encourages clear communication, ensures

manufacturability, reduces misunderstandings, and minimizes costly revisions

during mass production, directly lowering supply chain risks.

Is

sheet metal prototyping cost-effective for small businesses?

Absolutely. While prototyping requires an initial

investment, it prevents major losses by avoiding defective batches, delivery

failures, and supply chain disruptions. For small businesses, this cost-saving

advantage can significantly improve profitability and resilience.

By standardizing specs and validating manufacturability up front, sheet metal prototyping turns uncertainty into a controlled, repeatable process. Ready to de-risk your next build? Contact UIDEA for a fast prototype pack and a quote.