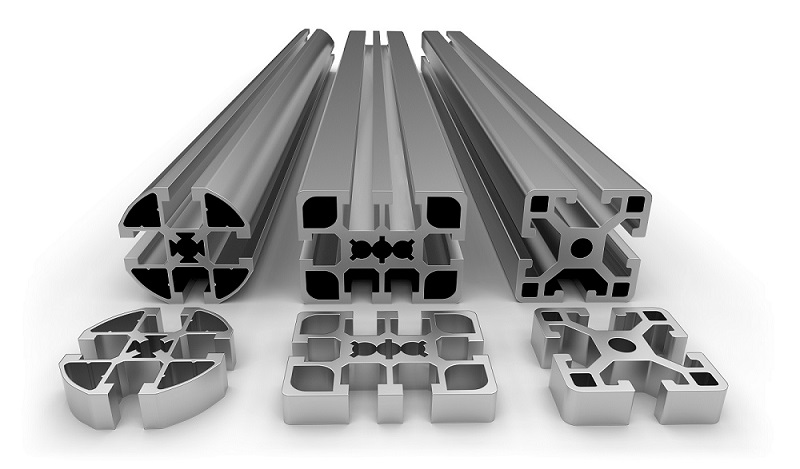

Like any other extrusion

process, the Aluminum extrusion technique is used to transform aluminum alloy

into different aluminum parts with fixed cross-sectional profiles for a wide

range of industrial use. As per the industrial requirements, a definitive

cross-sectional profile can be rectangular, solid round, L shapes, T shapes,

and Tubes, etc. The extrusion process is done by pushing the aluminum in

a die by using a hydraulic or mechanical press and then it emerges from the die

opening in the same shape as the die.

The extruded aluminum

parts are used in a variety of industries including aerospace, automotive

industry, electronics, medical equipment manufacturing, telecommunication

projects, construction, and many more. That is where an aluminum extrusion

process comes into the picture to create custom aluminum profiles such as bars,

hollow shapes, semi-hollow shapes, solids, tubes, and other custom shapes for

different industrial use.

To achieve the high-quality

objectives, industries prefer to go through the aluminum

extrusion prototyping process first to set high-performance expectations

from the end product. The prototyping process offers a lot of advantages to the

industries if they are not familiar with the aluminum extrusion process. You

should be aware of the functions and usage of the extruded aluminum parts and

ask these basic questions to yourself before opting for an aluminum extrusion

service:

·

What

is the key purpose of your component?

· How will it appear in the end product?

· How will the extruded aluminum part fit?

· What function will it serve in your industry?

Typically,

an Aluminum Extrusion process involves these steps:

· An extrusion die is designed and prepared based on the cross-section profiles and shapes for different industrial objectives. The extrusion die is then moved to the extrusion press.

· A cylindrical billet of aluminum alloy is heated to 400-500 degrees Celsius before extrusion. It makes aluminum alloy malleable enough, but not molten, for the extrusion process.

· A lubricant is added to the aluminum billet to prevent it from sticking to the machine and then transferred to the extrusion press.

· The extrusion machine ram pushes the aluminum billet into the container which then emerges through the pre-designed die.

· Then the extrusions are guided onto a run-out table in the same shape as the die opening as an elongated piece.

· Extruded parts are pulled to the cooling table where they are cooled to room temperature using the fans.

· Once the cooling process is completed, aluminum extrusions are moved to a stretcher for straightening and alignment work.

· After that, extruded aluminum parts are brought to the saw table and cut to length as per the requirements and then moved for finishing and fabrication works.

If you are looking for

Aluminum extrusion prototyping and production

services,

search and find the right manufacture for your industrial requirements. Look

for the kind of services they offer and how experienced they are in the

industry. Consider consulting with professional manufacturers to find the best

solution for your needs. You can check for the online reviews, and testimonials

to get an idea about their professionalism and how good they are at their

works.