Rapid prototyping is a

group of processes and techniques used to fabricate a physical model of end

parts using 3D CAD data. It is a quick way to transform an idea into a

successful prototype before starting the final production of any physical part

or assembly. It is an essential stage of the product development process in any

manufacturing industry to create a concept model and validate the details for an

accurate representation of the finished product. Rapid Prototyping is used in a

wide range of applications and industries.

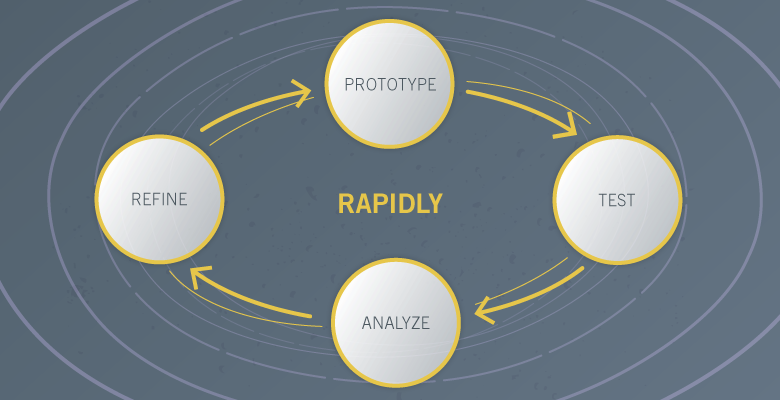

Typically, rapid

prototyping employs a range of methods to visually and functionally evaluate

and validate an engineering product design. The process of creating a 3D scale

model of any assembly part involves various stages to create an actual replica

of the final product. The most common stages of rapid prototyping include

concept visualization, prototype design, review, validation, and refinement to

design a concept model. The cost of rapid

prototyping services depends on various factors such as volume, height,

orientation, material, and finish depending on the industrial requirements.

Types

of Rapid Prototyping Techniques:

Different industries use

different technologies to fabricate a 3D scale model quickly and effectively. Depending

on the industrial use and application, choosing the right technology is

critical for successful prototype fabrication. Engineering product designers

use the following technologies for rapid prototyping:

· CNC Machining Prototyping

· Stereolithography (SLA)

· Selective Laser Sintering (SLS)

· Selective Laser Melting (SLM)

· Direct Metal Laser Sintering (DMLS)

· Vacuum Casting

· Fused Deposition Modelling (FDM)

· Digital Light Processing (DLP)

· Binder Jet 3D Printing

Rapid Prototyping is also

referred to as 3D

printing to fabricate a physical design from a virtual design using computer aided

design (CAD) software and other manufacturing technologies. Prototype engineers

use more than one technique to assemble a 3D scale model during the prototype

manufacturing process. In Rapid Prototyping, CAD data translates to the 3D

prototyping machine to fabricate the final prototype based on a standard data

interface.

Advantages

of Rapid Prototyping:

Rapid prototyping has

various industrial advantages in any engineering product manufacturing process.

Some of the most attractive advantages are:

· Reduced design and development time

· Overall lower product development cost

· Eliminate design and functional error at early stages

· Enables virtual and functional testing

· Test more solutions and incorporate changes quickly

· Reduced material wastage

· Minimize design flaws

· Allows customize product design using CAD software

Rapid prototyping services are

used in a wide range of applications across various industries such as

automotive, medical, and aerospace to fabricate a 3D scale model of assembly

pars. It is a time and cost-effective process to transform an idea into an actual

product effectively in quick time. If you are looking for product prototyping

services,

try to find a company with years of experience in the industry using different

technologies and tools to create an accurate prototype model as per the client’s

requirements.