Design and development of new medical products used to be expensive and time-consuming. However, it is no more the case- thanks to rapid prototyping. Rapid prototyping is convenient for concept and market testing of your medical products including handheld appliances and large equipment. You might be wondering now what rapid prototyping is. That’s what we are going to discuss in the next part of this blog.

What is rapid prototyping?

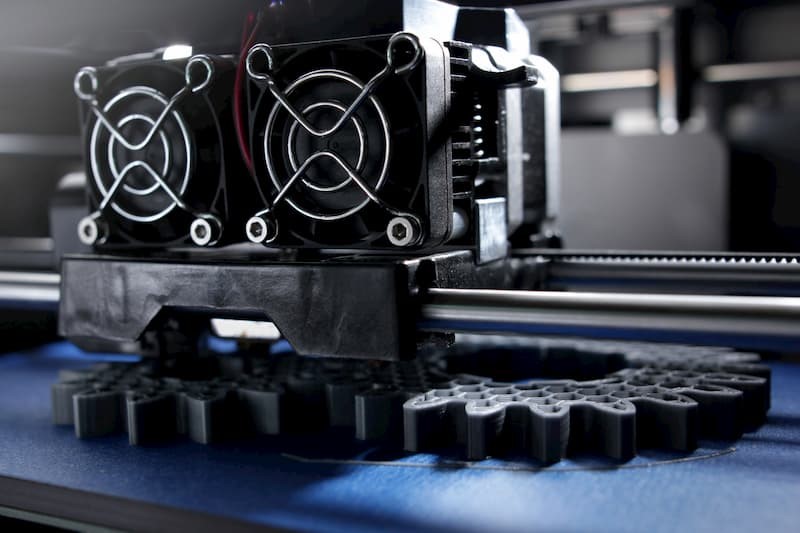

Rapid prototyping is the quick fabrication of physical parts with the help of computer-aided manufacturing and design technologies. Many sectors including healthcare, have started utilizing rapid prototyping technology. It is used to produce low-volume production parts. Moreover, it keeps the cost in check along with boosting the speed of the development cycle. Thus, it helps businesses test new ideas without spending a lot. Moreover, new manufacturing technologies deliver a working prototype to a customer in a few days. Further in this post, we are going to highlight the five most commonly used rapid prototyping methods to create prototypes in the medical industry.

5 most commonly used rapid prototyping methods

CNC machining

It is a subtractive process that provides a quick way to produce highly accurate as well as functional prototypes. State-of-art, five-axis CNC machining offers a cost-effective way to get prototypes having complex geometry.

Clear acrylic machining & polishing

CNC machining of clear acrylic followed by hand, vapor, or flame polishing, offers prototypes with a high level of optical clarity. So this technique works best when clarity and dimensional precision are the most important goals. It is ideal for the creation of lenses and prisms required in laser instrumentation and other medical devices.

Aluminum machining

It offers an advantage when working with low-density and high-strength substances. The aluminum alloys are machined to close tolerances and polishing after that removes all the little imperfections to further enhance the object.

Reaction injection molding

Reaction injection molding or RIM is used for producing strong lightweight prototypes along with a high-density skin and lower-density core. The process of RIM helps the production of more complex prototypes than are possible with traditional injection modeling.

Vacuum casting

Vacuum casting is used for the rapid prototyping in China of organ models such as a heart. A master mold is fabricated from laser-etched silicon resin after that, an extra soft resin is used to produce the prototype.

To sum up

Rapid prototyping plays a vital role in technological advancement in the medical industry. It allows virtual simulation, experimentation, and realistic representation of what we want to make in reality. It allows one to try out multiple models with design variations within the shortest time possible. Moreover, its potential is way more than we have realized now.