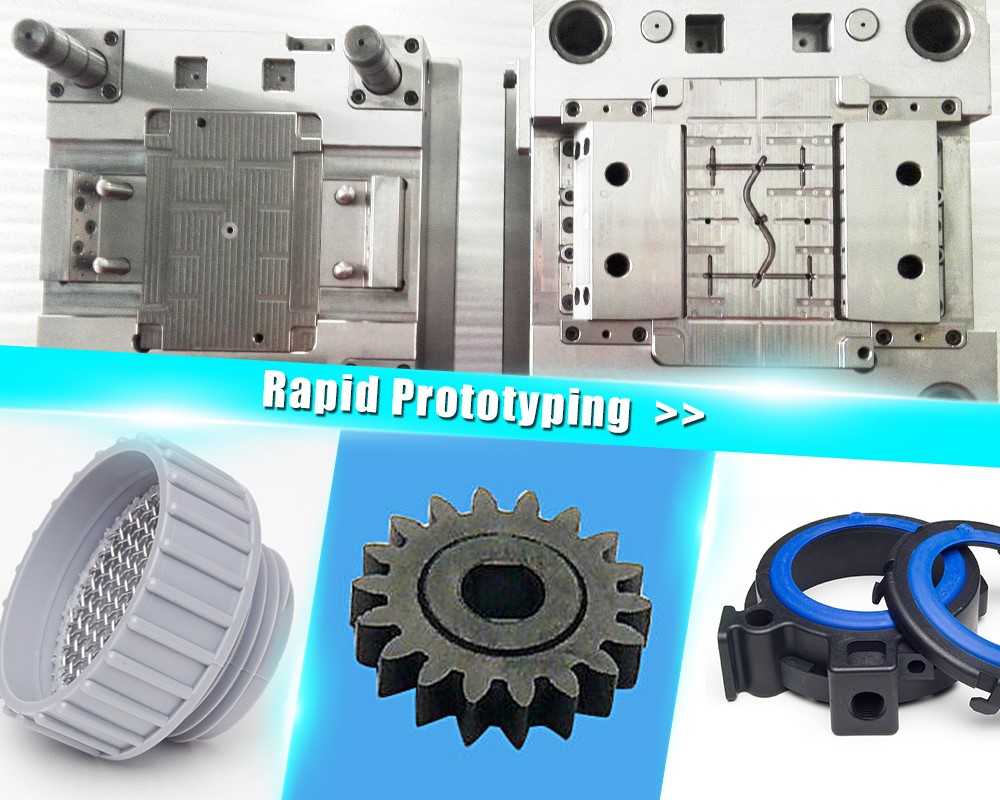

When it comes to hiring services for rapid prototyping in China, it is crucial to select the right material beforehand. Different types of plastics are available in the market and each of them varies in strength, appearance, and durability. However, choosing the best approach and the right plastic for rapid prototyping on your own can be daunting.

At such times, getting advice from a professional can greatly help. In most cases, companies that offer rapid prototyping services can help you guide in this direction.

In this post, we will discuss five commonly used plastics in prototyping to help you get an idea of what options of plastics you have for your application.

Commonly Used Plastics for Rapid Prototyping

1. Polycarbonate (PC)

PC is a thermoplastic resin that is amorphous in nature. It is widely used for prototyping applications owing to its excellent electrical insulation, extensibility, chemical resistance, heat resistance, high strength, cold resistance, and dimensional stability. Components, such as gear, rack, worm, lever, crankshaft, and ratchet are typically made from PC. Its strength is considered to be higher than PMMA.

2. Poly(methyl methacrylate) (PMMA)

PMMA is a commonly used transparent plastic material known for its applications in a wide range of products, such as car windows, smartphone screens, aquariums, skylights, and so on. It is rigid, strong, and light in weight. Besides, it has exceptional optical clarity, dimensional stability, surface hardness, and weather ability. Due to its transparency, it is widely used as a substitute for glass.

3. Acrylonitrile Butadiene Styrene (ABS)

ABS is a low-cost general-purpose thermoplastic polymer with remarkable properties, such as good impact strength even at low temperatures, high rigidity, mechanical strength, chemical resistance, and more. Besides, it has high tensile strength and is almost unbreakable. Therefore, it finds its wide usage in all kinds of prototype processes and manufacturing bodies of various electrical and medical appliances. Plus, it can be painted, metalized, and decorated to achieve the desired appearance.

4. Polypropylene (PP)

It is another very commonly used type that is light in weight, translucent, colorless, odorless, and non-toxic. Due to its structural regularity and a high degree of crystallization, this plastic is preferred for parts that need some flexibility, in injection molding processes, and also used in automotive interiors as it doesn’t react with most materials and resists cracks and stress. However, it is hard to paint or glue.

5. PolyStyrene (PS)

PS is a highly versatile plastic generally used for making a wide variety of consumer products like jewel cases, smoke detector housings, license plate frames, and so on. It is often used in products that need clarity, for instance, food packaging and laboratory ware. When it is combined with various colorants, additives, or other plastics, PS is also used to make parts of appliances, electronics, automobiles, toys, gardening pots, equipment, and more.

Apart from these, there are various other plastics that might be right for your application. Some examples are PVC, POM, Nylon, photo-curable resins, etc. So, before making a selection, gather detailed knowledge about your plastic options to come up with the best choice of material for rapid prototyping.