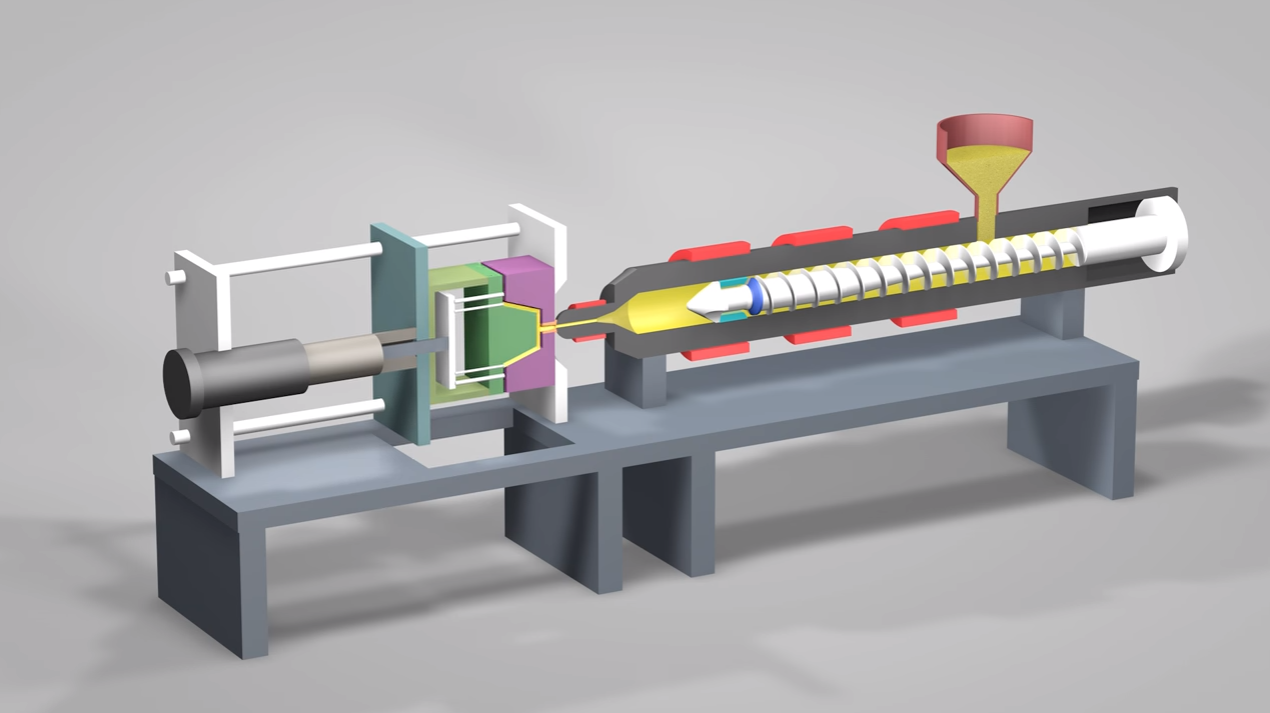

Injection molding is mainly a procedure of creating products or finished parts by forcing molten plastic into a mold and further allowing it to harden. The uses of these finished parts vary widely as the variety of products made from the molding process. However, depending on its use, the injection molded parts can weigh from ounces to thousand pounds, or you can say from toys and computer parts to auto parts and truck.

The Benefits of Injection Molding:

The injection molding process has gained in popularity over the recent years because of the benefits that it offers over other die casting manufacturing methods. Some of the major benefits of this process include:

· Low labor cost

· High result production

· Fast production

· Design flexibility

· Leaves less post-production scrap and waste

· Can be utilized to make very small parts

· Different materials can be used at the same time

On the other hand, if you are finding a company that can cater to all your needs to produce products with specific measurements, you might be faced with difficulty with the fact that there are several Injection Molding Services out there, and choosing the right one maybe not that easy for you. However, by considering the below-given factors, you’ll be able to eliminate any confusion and hire the right service provider.

1. Reputation:

Considering the reputation of the molding service provider is very essential for the success of your project. The reputation of the company can be measured by a number of factors such as financial performance, organizational ethics, quality of products, reliability, and so on. Additionally, this also includes the service provider’s digital reputation that can drastically influence customers trust in the business.

2. Efficiency and Quality of the Service:

In addition to having a well-built rapport, your injection molding partner should also be committed and equipped to provide you with the best service and facilities possible. Answers to these below-given questions will surely help give the necessary insight for you to choose an injection molded that best fits your company’s requirements and preferences.

· Does the injection molding service own efficient and top quality machines for the process?

· Does the company focus more on the removal of dysfunctional variability including the organizational problems that can cause late delivery of the project?

· Does the company provide a maintenance program?

· Has the company been recognized in the industry?

3. Additional Services and Technology:

Not all injection molding services offer expanded or additional help required to design parts for manufacturability. Therefore, working with a company that also offers part design services, prototyping, in-depth mold flow, quick response and more will help you develop timing efficiencies and valuable cost in regard to launching your product to the market.

It is very important that you partner with an injection molding service that understands all your needs and challenges in order to get success for your product. And taking these factors into account will definitely help you streamline the entire procedure of selecting an injection molding service provider for your company.