Look around your home, and there are many appliances as well as construction around you that incorporates sheet metals in various ways.

This material has been used for different purposes and objectives for ages across the world. Well, what makes this possible is sheet metal fabrication.

What is Sheet Metal Fabrication?

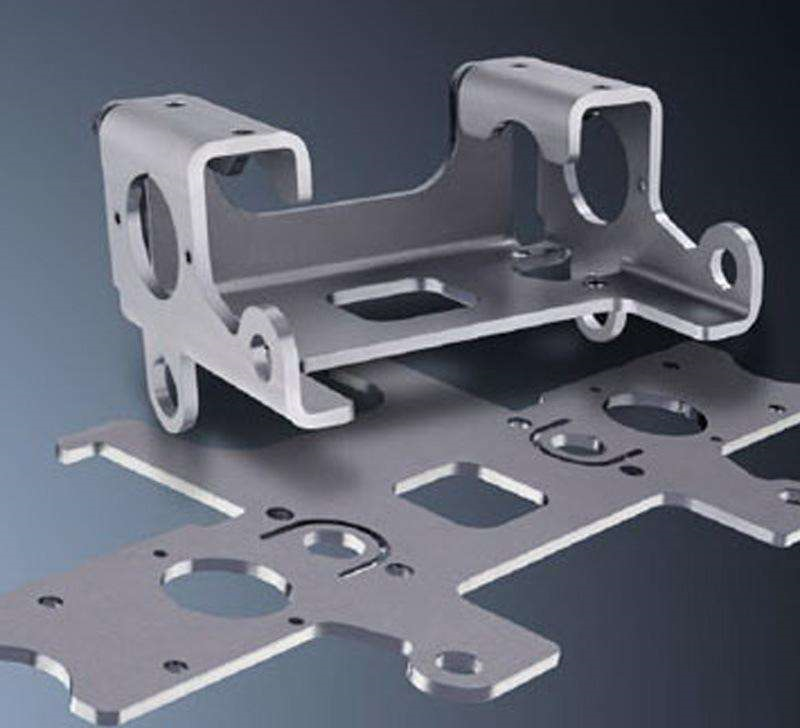

When metal sheets are formed specific to the required shape with various manufacturing methods, this is called as sheet metal fabrication. Different types of sheet metal fabrication techniques are used depending on the end-result, need and costing.

When you are looking for sheet metal fabrication in China, or elsewhere, then having a comprehensive knowledge in this field is helpful to make right and informed choices.

Sheet Metal Fabrication Process

It is not that sheet metal fabrication is a single step; but it consists of different steps and process types. It starts with CAD engineering, and then each part goes through specific process, as detailed below:

1. Thermal Cutting

Thermal or laser cutting is a common method to cut the sheets. It is very precise and can be done quickly. When the cutting has to be done for thicker materials (more than 10mm) then plasma cutting option may also be taken up. However, considering the quality of precision in cutting, laser cutting is preferred.

2. Mechanical Cutting

This method is die cutting or shearing which is applied without any need for melting or burning the sheet metals. Shearing is like cutting with a scissor which is a cost-effective method and is suitable whenever there is no requirement for complex cuts.

3. Bending

Most of the metals that come into the workshop for fabrication process, goes through the bending section. Bending can be a complex process and therefore knowledge of proper bending limitations of the specific sheets is necessary.

4. Punching

As the name suggests, punching is used when there is a requirement to cut holes into a sheet. It is done with perforating and is ideal to apply when the end-result requirement is large-scale production.

5. Assembling

In a sheet metal fabrication process, assembling is the penultimate step. Sometimes assembling may include welding, and for that the parts must be thoroughly cleaned beforehand, followed by powder coating. If there is no need for welding, then after powder coating the metal parts are joined using methods like bolting and riveting.

6. Powder Coating

In this, a charged metal component is taken and is applied with electrostatic powder as the surface treatment. This treatment is suitable when there is no requirement pertaining to acidic or wear-heavy environment.

Sheet metal fabrication in China or anywhere else, helps to create the preferred shape and quality metal sheet including cold rolled steels, hot rolled steels, aluminium sheets or stainless steel sheets.