In recent years, 3D printing technology has evolved in order to produce high quality visual models. Due to advancements in 3D printing such as Stereolithography i.e. SLA rapid prototyping and PolyJet, you can achieve a vibrancy in the visual models which is nearly impossible to achieve with other technologies. Here, we will discuss two popular 3D printing technologies i.e. SLA and PolyJet and also share some differences which make these two three dimensional technology forms distinct from each other.

Stereolithography –

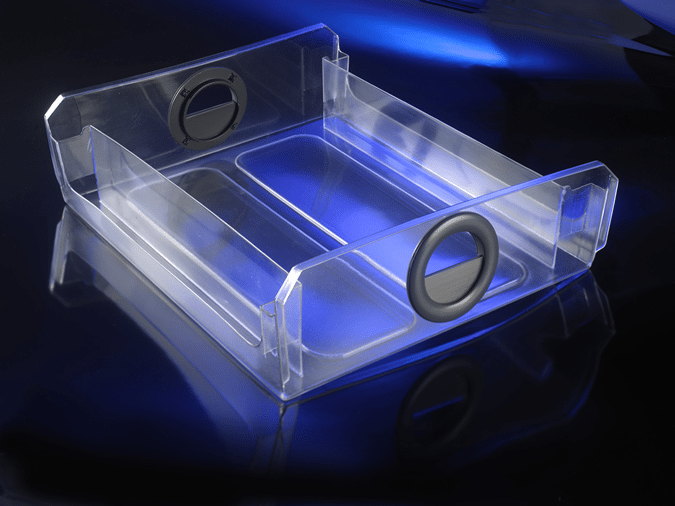

Stereolithography (SL or

SLA) is a type of 3D printing technology which is widely used for creating

prototypes, models, patterns and production parts in a layer by layer style

with the aid of photo polymerization. Here, photo polymerization is a process

in which light causes chemical monomers to link or join together in order to

form polymers.

PolyJet –

PolyJet is also a 3D printing technology used for prototyping, modeling and production applications. It builds parts with photopolymers resins/photo curable material and is used to print color directly into a part.

You can easily notice that both of the above technologies use photopolymer material to additively build detailed prototypes. SLA rapid prototyping and PolyJet process use UV energy to cure plastics, however, their different building styles separate them in terms of materials and applications.

If you know the difference between these two forms, you can easily figure out which one is suitable for your project. So, here are the four differences between SLA and PolyJet.

Differences between SLA and PolyJet-

1. Build Style -

SLA uses UV lasers which are directed through dynamic mirrors onto a bed of liquid plastic to cure patterns, cross-section by cross-section. It prints in 0.002” layers at its finest. On the other hand, PolyJet uses multiple print heads to deposit liquid plastic onto a build platform layer by layer and the material is cured as it is deposited. It can deposit material in layers as fine as 16 microns. Though it is the fastest technology within a 5” cube, it becomes slower outside this limit. In contrast, size doesn’t matter in Stereolithography.

2. Post-Processing -

SLA supports are created out of the same material as the final part and must be sanded and removed by hand. SLA parts are not built fully cured so that excessive resin can be drained out and thus, they require additional curing in a UV oven. Conversely, PolyJet supports are created out of a separate material specially formulated to release from the final part with water blasting and hand labor. While PolyJet prototypes, models and parts have a smoother surface right off the build, SLA rapid prototypes offer much ease to sand the surface.

3. Material -

SLA materials are available in rigid, clear, grey, white opaque and specially formulated plastic for investment casting patterns. On the contrary, PolyJet materials can be availed in all colors, opaque and transparent, as well as rigid and flexible form.

4. Applications -

The speed and fine

resolution of PolyJet make this form ideal for only small and highly detailed

prototypes and master patterns. However, SLA is ideal for large prototypes and

master patterns. The main advantage of SLA is that it has the ability to print

mostly hollow parts using an interior honeycomb structure. SLA hollow parts are

mainly used in investment casting whereas PolyJet is ideal for multi-material

(hybrid) printing.

So, after analyzing your application or project, you can easily determine whether or not you require SLA rapid prototype. In case, you are in a dilemma which technology form would be suitable for your application, just contact one of the reputed rapid prototype manufacturers and consult with the professionals directly.