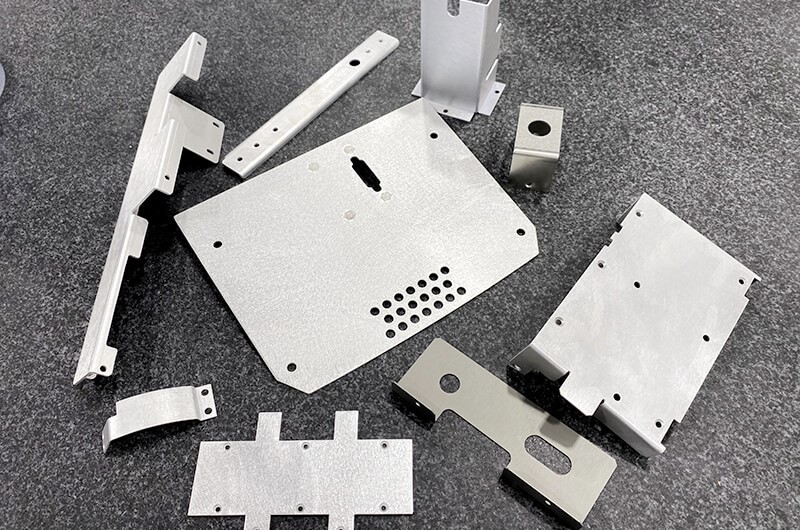

China is a worldwide manufacturing hub. Here, sheet metal prototyping plays a vital role in product development and innovation. However, ensuring excellence in creating sheet metal prototypes necessitates strategic planning, careful execution, and using local experience. Further in this blog, we have highlighted the top tactics for the following six tactics that are crucial for effective sheet metal fabrication in China.

Embrace Advanced Technology

China is well known worldwide for its modern industrial facilities and access to advanced technology. So businesses need to use cutting-edge sheet metal fabrication technology like robotic welding, CNC machining, and laser cutting if they want to attain excellence in the sheet metal prototype. They can improve sheet metal production's accuracy, effectiveness, and quality by investing in contemporary technology, which paves the way for successful prototyping initiatives.

Collaborate with Experienced Partners

Working with respectable sheet metal fabrication manufacturers guarantees access to technical knowledge, industry insights, and dependable manufacturing capabilities. So for the prototype to be successful, creating strong partnerships with knowledgeable sheet metal fabricators and suppliers is essential. By utilizing the expertise and assets of reliable partners, companies may reduce risks, expedite the prototype process, and provide better results.

Prioritize Design Optimization and DFM Analysis

Design for Manufacturability (DFM) analysis and robust design optimization are the first steps in the development of effective sheet metal. When refining product designs for manufacture, engineers, and designers must collaborate closely to take material selection, tolerances, thickness, and assembly needs into account. Early design optimization at the prototyping stage helps manufacturers cut costs, shorten lead times, and improve production feasibility and efficiency.

Streamline Tooling and Molding Processes

Precision molds for sheet metal components are made in China by manufacturers using injection molding processes and cutting-edge tooling technology. They can achieve consistent outcomes across production batches, enhance part accuracy, and expedite prototyping times by optimizing their tooling and molding processes. Toolmakers and design teams must work together and communicate effectively for tooling solutions to be seamlessly integrated into the prototype process.

Rigorous Quality Control Measures

Enforcing stringent quality control procedures during the prototype phase facilitates the early detection and resolution of any possible flaws or irregularities. Coordinate measuring machines (CMM) and optical inspection systems are two examples of sophisticated inspection methods used by manufacturers to confirm the dimensions and integrity of their products. These manufacturers also follow international quality standards and certifications. Businesses may establish a reputation for excellence and dependability and inspire trust in their prototypes by placing a high priority on quality assurance.

Iterate, Test, and Iterate Again

Manufacturers are able to optimize design parameters, improve product performance, and find opportunities for improvement through iterative cycles of testing, assessment, and feedback. Prototyping facilities in China provide extensive testing capabilities, such as thermal testing, environmental simulation, and structural analysis, to verify prototypes in real-world scenarios. With this, businesses may enhance their ideas and make sure that the finished product meets or surpasses client expectations.

In the end

China is a global hub for manufacturing however ensuring excellence in sheet metal fabrication in China necessitates a balance of careful planning, technological innovation, collaboration, and commitment to quality. By keeping the above tips in mind, businesses can navigate the complex landscape of sheet metal prototypes. We hope that you find this blog helpful; however, if you still have any doubts about sheet metal prototyping, feel free to get in touch with the experts.