If you are facing the scarcity of the time rapid Injection Molding is the solution. This will greatly help in minimizing the time that was initially needed to have desired models completed. These products are not the finished products which are produced by the Rapid Injection Molding, but can be used while the true production mold is being manufactured. This process improves the product designing because it is a research and development process.

Designing is imperative -

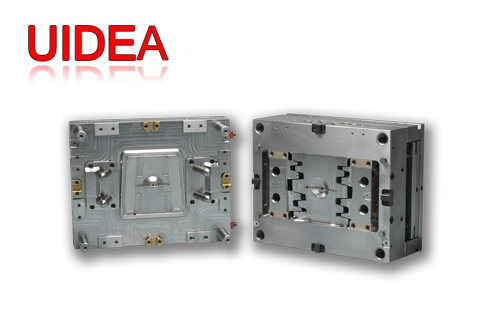

Designing is the vital step of the Rapid Injection Molding and is done with utmost care. The designing of the product ensures its performance. It ensures its look and the function. A clear concept of the product functionality is conceptualized. In the designing the big intricate parts are broken down into smaller parts. In these small intricate parts the rapid injection molding technique is used. By this the engineer can avoid the complexity of the design. Once the designing is done, then the product is assembled back into one unit. This is the reason that engineers are able to do the complex designing within the limited time and design the complex product.

There is something which is out of the trajectory of the Rapid Injection Molding -

Rapid injection molding is not the solution of all problems. It is not possible to shorten all processes by this technique. There are certain things which are out of the trajectory of this technique. It does not matter that if you have endless recourses and put a lot of effort, some process will take time.

Take advantage of the ready material -

There are many materials which are ready available. The retailer or a major distributor can provide you the material within the little span of time. If you send the time in finding the suitable material, it is against the very idea of Rapid Injection Molding. If you spend the time here the overall time of manufacturing will increase.

Pursuit of reducing the time taken should not bleed your pocket -

The turnaround time should be reduced by the rapid injection molding. It is obvious that if we try to reduce lead time, it will increase the cost of the process. There is need of the analysis of the extra coast cause by the extra resources. These recourses could increase the coast. It is advisable to compromise the process like extra man hours, material procurement, tool design, tool machining to make an appropriate balance between speed and cost.