In the rapidly evolving field of manufacturing, where efficiency, rapidity, and affordability are critical, businesses are continuously searching for cutting-edge technology to realize their concepts. Vacuum casting China and molding and tooling are such creative approaches that have become very popular. Numerous benefits provided by this manufacturing process make it the method of choice for many different businesses. We are going to explore the main benefits of using vacuum casting China services. Let’s start.

Accuracy and Detail:

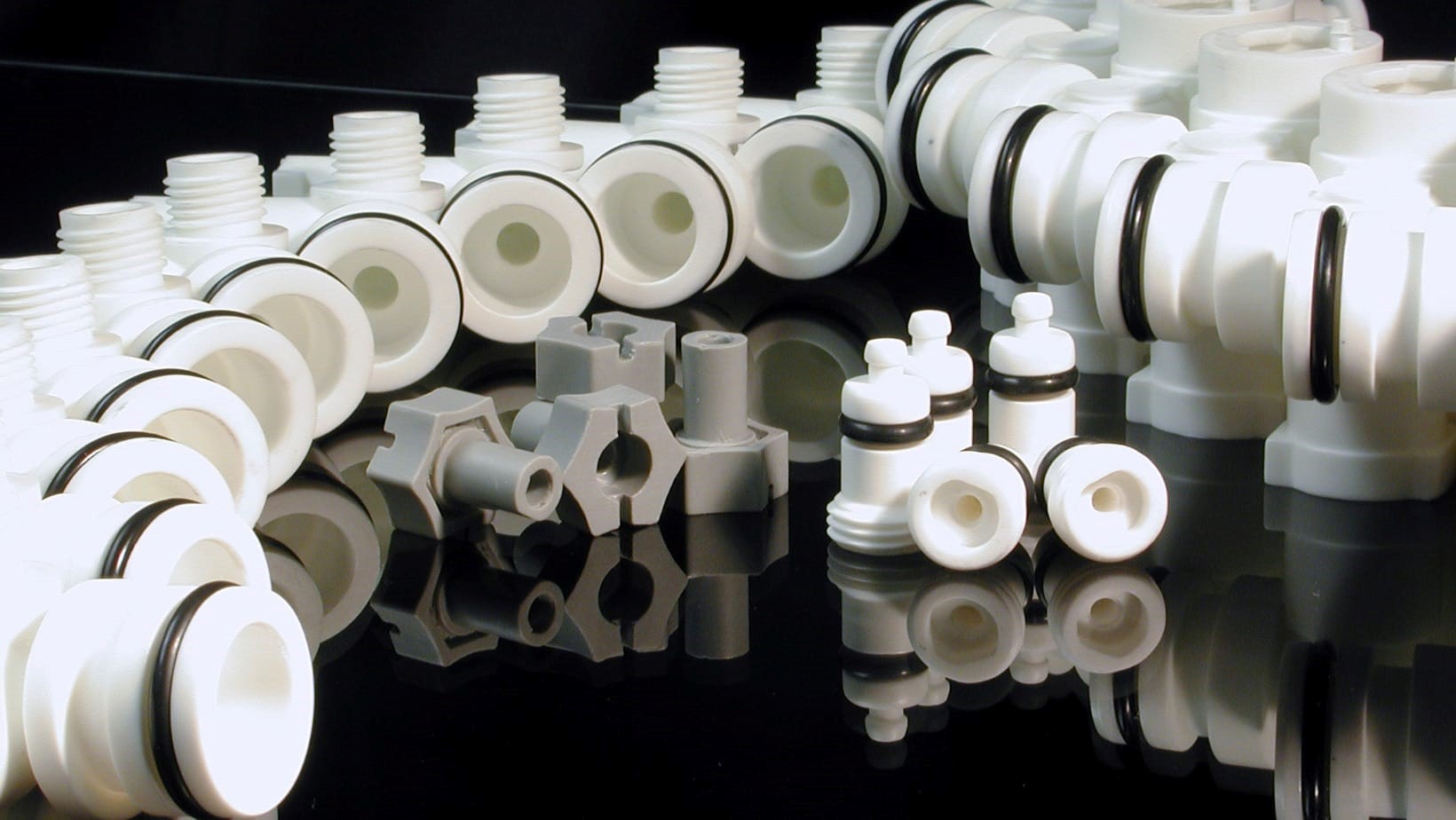

The capacity of vacuum casting to create incredibly delicate and detailed pieces is well known. A silicone mold is made from a master design during the procedure, which enables superb reproduction of subtle characteristics. For sectors like consumer electronics, automotive, and aerospace, where precise dimensions and elaborate designs are required, this precision is essential.

Economical Modeling:

Vacuum casting has several notable benefits, one of which is its affordability, particularly during the prototyping phase. Vacuum casting has lower setup and tooling costs than conventional manufacturing techniques like injection molding. Because of this, it's the best option for businesses who want to experiment and iterate on different design concepts without going over budget.

Rapid Reaction Time:

In today's competitive economy, time-to-market is crucial. One feature that makes vacuum casting unique is its ability to prototype quickly. The method drastically cuts down on the amount of time needed to make a batch of prototypes by enabling the manufacture of many copies from a single mold. Businesses trying to accelerate their product development cycles will find this short turnaround to be extremely helpful.

Flexibility in the Choice of Materials:

Many materials, such as silicones, optically clear resins, and different polyurethanes, can be used in vacuum casting. Because of the material's adaptability, manufacturers can select the precise qualities that their prototypes or finished goods require. A wide range of material needs can be accommodated via vacuum casting, from rigid to flexible, clear to opaque.

Production at Low Volume:

Vacuum casting is a great way to prototype, but it's also a good option for small-scale manufacturing. This is especially useful for specialist items or niche markets where large-scale manufacturing might not be financially feasible. Small quantities of excellent parts can be produced by businesses without requiring costly tooling setups.

Difficult Geometries:

Undercuts and complicated geometries can be challenging for conventional manufacturing techniques. On the other hand, vacuum casting works well with complex shapes and difficult designs. Because silicone molds are flexible, intricate characteristics that would be costly or difficult to replicate through other means can be replicated in pieces.

There are a variety of benefits associated with selecting vacuum casting services that cater to the changing demands of contemporary production. Vacuum casting has shown to be a versatile and successful option due to its ability to handle complicated geometries, appropriateness for low-volume manufacturing, cost-effective prototyping, short turnaround times, and precision and detail possible. Vacuum casting remains a dependable and essential technology for realizing concepts as industries push the boundaries of innovation.